Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

Disc grinders

Disc grinders are designed for comminution of samples of bulk materials to a fine-grained state.

In disc grinders, comminution occurs by means of abrasion – simultaneous compressive and shear strain of material particles between fixed and moving discs.

The grain size of the comminuted product is regulated by the gaps between the discs (openings) and the physical properties of the material.

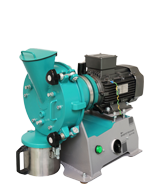

The Disc grinder DG 65 is designed for comminution of small samples weighing up to 1.0 kg for analytical studies with strict requirements relating to sample purity: the sample is not contaminated by working parts of the grinder.

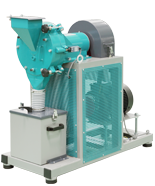

The Disc grinder DG 175М is a tabletop model of the DG 175. In addition to the reduced overall dimensions of the grinder, the method for adjusting the gap between the discs has been changed. This makes it possible to perform the adjustment while the electric motor is operating.

The Disc grinder DG 200 is a more powerful model of the laboratory-class equipment. It can be used for comminution of small samples weighing up to 3 kg, as well as for continuous comminution, by outfitting it with 1.8L or 10L receiving containers, as well as Feeders VF 1 or VF 2.

The Disc grinder DG 250 is high-power equipment designed for busy laboratories or small production facilities.

|

DG 65 |

DG 175М |

DG 175 |

DG 200 |

DG 250 |

|

|

Technological parameters |

|||||

| Average product particle size at minimum gap, mm | 30-40 | 40-50 | 50-70 | ||

| Product particle size at minimum gap, mm | 90%<50 | 90%<71 | 90%<100 | ||

| Maximum initial material grain size, mm* | 3 | 10 | |||

| Mohs hardness of comminuted material, up to | 8 | 8** | 7 | ||

| Output, kg/hour* | 1-5 | 5-100 | 10-150 | 15-200 | 20-250 |

| Technical parameters | |||||

| Hopper loading door dimensions, mm | Ø50 | 80х165 | 95х185 | 95х185 | |

| Grinder loading door dimensions, mm | Ø11 | 11,5хØ32 | |||

| Discharge slot adjustment range, mm | 0,05-2,0 | 0,07-5,0 | 0,1-5,0 | ||

| 50 Hz supply voltage, V | 220 | 380 | |||

| Electric motor power, kW | 0,37 | 2,2 | 4 | ||

| Disc rotation speed, rpm | 3000 | 1500 | |||

| Gross/usable capacity of the collecting container, l | 0,5/0,3 | 1,8/1,2 | - | ||

| Gross/usable capacity of the collecting tank, l | - | - | 12/8 | ||

| Overall dimensions (Length x Width x Height), mm | 350х225х300 | 625х375х485 | 630х410х925 | 930х410х935 | |

| Weight/weight with control panel, kg | 21/26 | 83/- | -/140 | -/165 | |

| Discs material – silicon carbide/iron/steel/iron with tungsten carbide inserts | SiC/-/-/- |

-/EN-GJN-HV600 (XCr14)/X20Cr13/EN-GJN-HV600 (XCr14) + tungsten carbide |

-/EN-GJN-HV600 (XCr14)/GX120Mn13/EN-GJN-HV600 (XCr14) + tungsten carbide | -/EN-GJN-HV600 (XCr14)/-/- | |

| Discs hardness – silicon carbide/iron/steel/iron with tungsten carbide inserts | 85-90 HRA/-/-/- | -/52-55 HRC/ 31-32 HRC/ inserts 1180-1280 HV | -/52-55 HRC/-/- | ||

| Compatible control panel | PCP1-03 | CCPB built-in control panel | MCP3-04 | MCP3-06 | |

* The maximum allowable size of the initial material depends on its physical properties.

**If discs with tungsten carbide inserts are used.

Advantages of VIBROTECHNIK Disc grinders:

- Use of discs with two types of working surface: wedge-shaped (for preliminary comminution) and flat (for regrinding);

- Positioning of discs strictly parallel to one another by adjusting the position of the fixed disc;

- Discs are made of wear-resistant materials: carborundum, high-strength iron or manganese steel;

- Increased disc service life (DG 175М, DG 200 and DG 250) due to:

- Ability to rotate the discs 180 degrees;

- Interchangeable moving and fixed discs;

- Reversible operation.

- Safe operation of the grinders is ensured by:

- Equipping the grinders with control panels;

- Limit microswitches that prevent grinders from being started with the covers or grinding chambers open.

- Openings for monitoring the gap between the discs are provided in DG 175М, DG 200 and DG 250 stationary chambers.

Applications: ferroalloys, ore, granite, marble, limestone, coal, coke, slag, diatomaceous earth, silica gel, automotive catalyst, glass, salt.

Industries: mining, metallurgy, construction, chemical.