Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

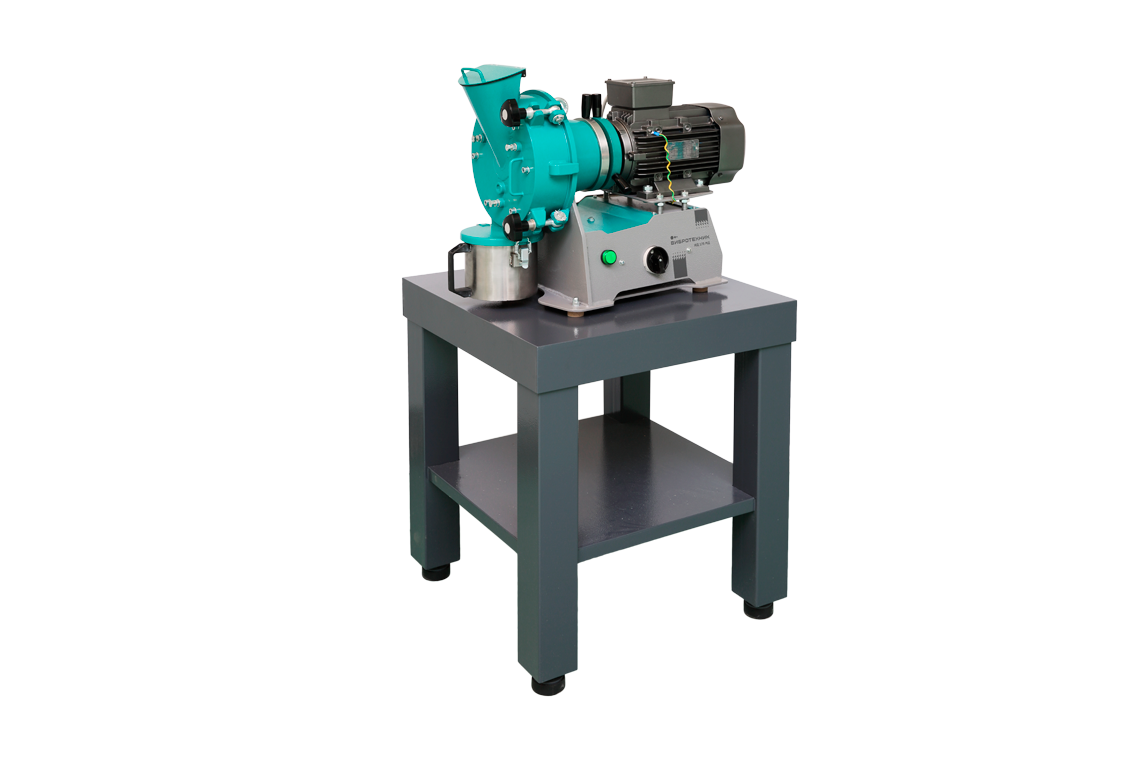

Disc grinder DG 175М

|

INDUSTRIES

|

APPLICATIONS Ferroalloys, ores, granite, marble, limestone, coal, coke, slag, diatomaceous soil, silica gel, automotive catalyst, glass, salt

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

| Average product particle size at minimum gap, mm | 40-50 |

| Product particle size at minimum gap, mm | 90%<71 |

| Maximum initial material grain size, mm* | 10 |

| Mohs hardness of comminuted material, up to | 8** |

| Output, kg/hour* | 5-100 |

| TECHNICAL PARAMETERS | |

| Hopper loading door dimensions, mm | 80х165 |

| Grinder loading door dimensions, mm | 11,5хØ32 |

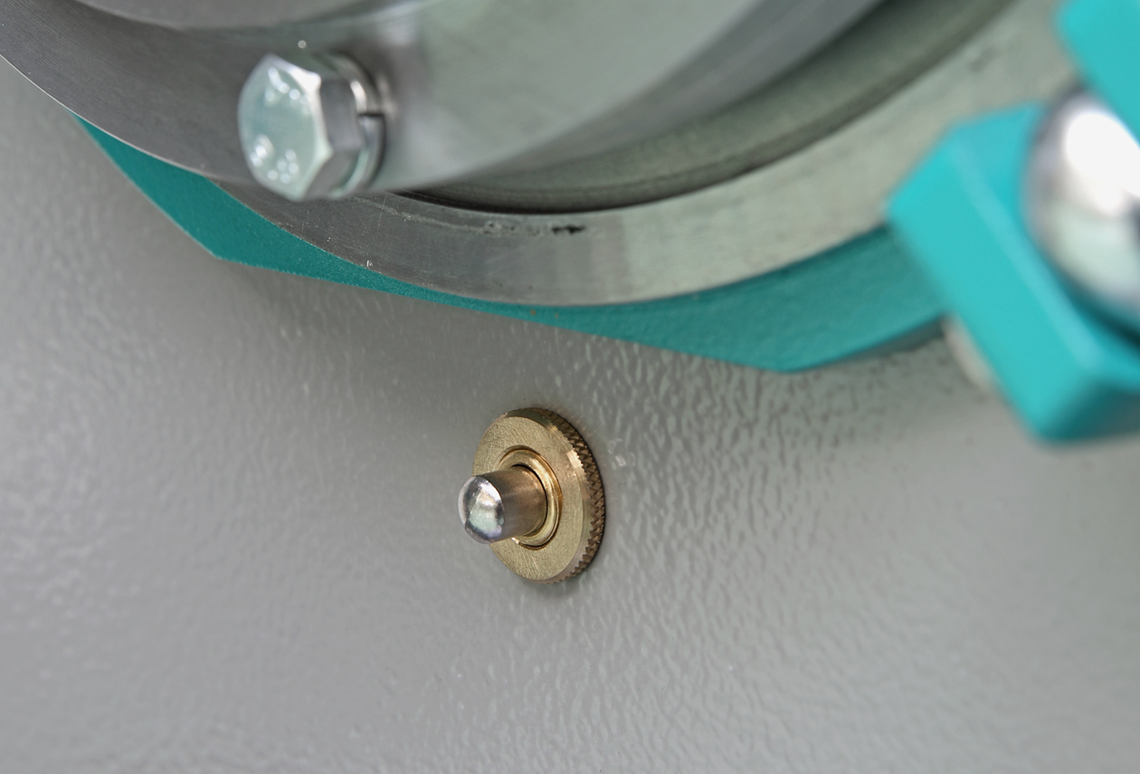

| Discharge slot adjustment range, mm | 0,07-5,0 |

| 50 Hz supply voltage, V | 380 |

| Electric motor power, kW | 2,2 |

| Disc rotation speed, rpm | 1500 |

| Gross/usable capacity of the collecting container, l | 1,8/1,2 |

| Overall dimensions (Length x Width x Height), mm | 625х375х485 |

| Weight/weight with control panel, kg | 83/- |

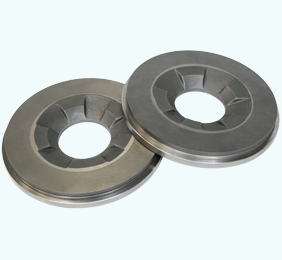

| Discs material – silicon carbide/iron/steel/iron with tungsten carbide inserts | -/EN-GJN-HV600 (XCr14)/X20Cr13/EN-GJN-HV600 (XCr14)+tungsten carbide |

| Discs hardness – silicon carbide/iron/steel/iron with tungsten carbide inserts | -/52-55 HRC/ 31-32 HRC/ inserts 1180-1280 HV |

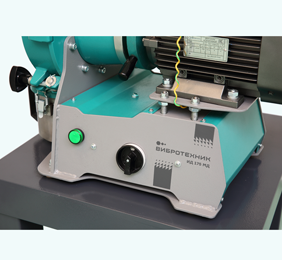

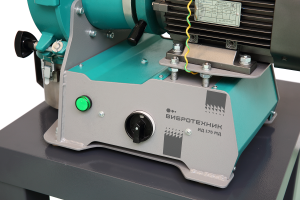

| Compatible control panel | CCPB built-in control panel |

* Depends on the hardness of the material and the discharge slot setting.

** When using discs with tungsten carbide inserts.

ADVANTAGES

|

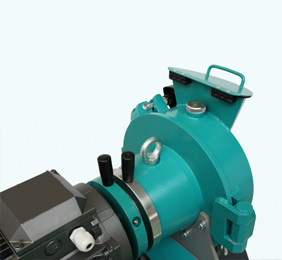

CONVENIENT ADJUSTMENT The adjustment device is located next to the grinding chamber. It is possible to set a minimum gap between the discs while the grinder is operating. |

|

|

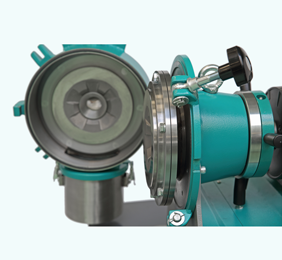

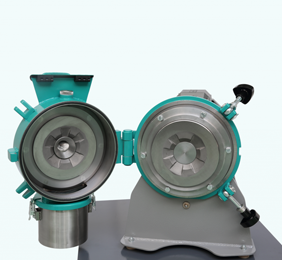

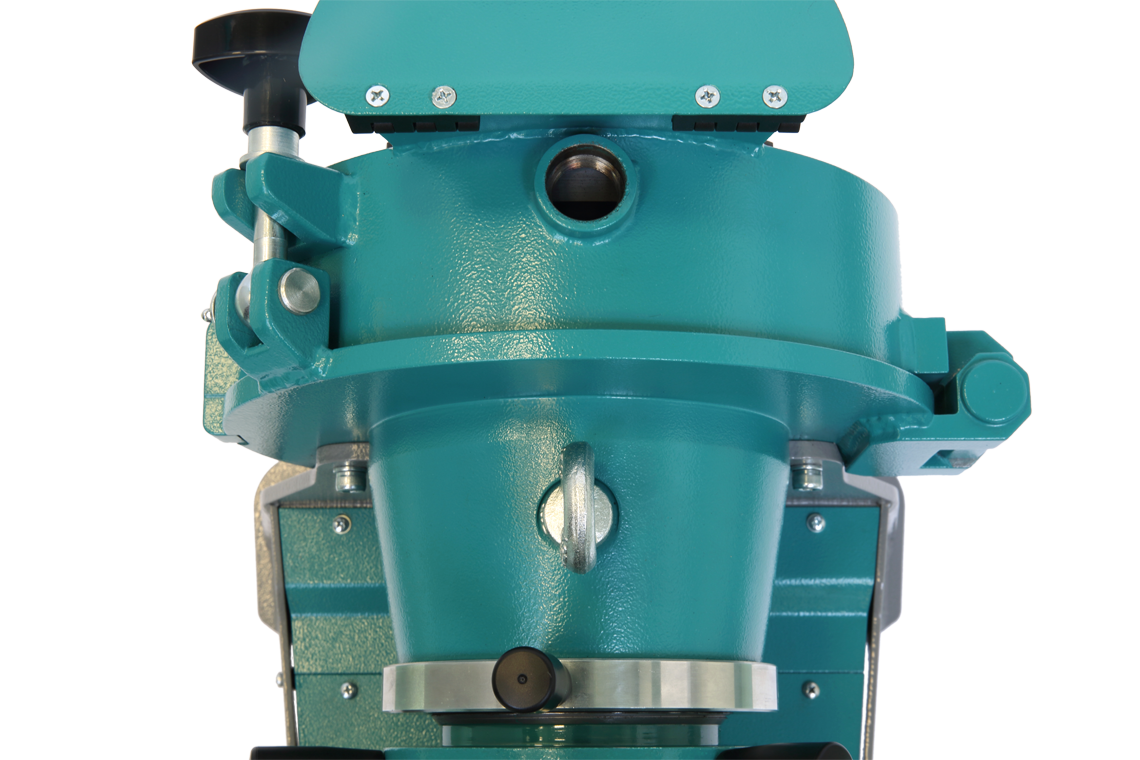

EASY CLEANING There are no gaps between the fixed disk and the folding chamber. Between the moving disk and the housing there is a gap for cleaning and blowing residual material off. |

|

BUILT-IN CONTROL PANEL The built-in control panel is designed to start and stop the grinder and provides:

|

|

|

FOLDING GRINDING CHAMBER The folding grinding chamber provides quick access to the moving and fixed disks for cleaning or replacing them. |

|

COMPATIBILITY WITH VIBRATORY FEEDER Supplement DG 175M with vibratory feeder VF 1 provides:

|

DESCRIPTION OF THE DEVICE

|

In DG 175M disc grinder comminution occurs due to abrasion — simultaneous compression and shear of the material. The structure of the grinder includes: a folding grinding chamber with loading and discharge funnels, a collecting container, moving and fixed disks, a housing with a drive shaft, a base and an electric motor. The particle size of the final product is determined by the gap between the disks (discharge slot). The gap between the disks is adjusted by moving the shaft with the moving disk in the axial direction. The surface of the disks on the periphery is flat and near the center it has a complex wedge-shaped form. The selected dimensions and angles of inclination of the troughs and teeth provide high grinding efficiency and reduce the load on parts and assemblies during grinding. OPERATING PRINCIPLE The material is fed into a loading funnel, from where it enters the working cavity between the disks through an opening in the center of the fixed disk. As a result of the action of centrifugal forces, the particles of the material move from the center to the edges of the disks, gradually grinding. The stream of crushed particles coming from the gap between the disks enters the grinding chamber, where the particles lose their speed and pour through a discharge funnel into a collection container. The output of the DG 175M disc grinder depends on the hardness of the material, the setting of the discharge slot, the initial grain size of the material and the required grain size of the product. |

End switch Opening to control the gap between the discs Collecting container, V=1,7 L DG 175M Disc grinder on T 70 stand Loading scoops, V= 0,07 L and 1,2 L |

.png)

.png)

.png)

.png)