Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

Hammer crushers

Hammer crushers are designed to crush brittle materials and break down conglomerates.

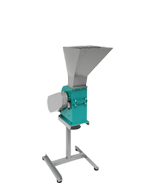

The Hammer crusher HC 2х2 is laboratory-class equipment designed to crush small batches of material with output up to 100 kg/hour.

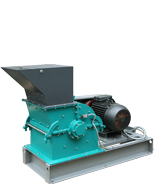

Hammer crushers HC 5х2 and HC 5х5 are industrial-class equipment used in busy laboratories or in small and medium-sized production facilities.

The operational principle of a hammer crusher is based on impact on material particles.

Material particles are broken down:

- when a hammer falls on them;

- when they impact the liner and walls of the housing;

- when the particles collide with each other.

|

Characteristics |

HC 2х2 |

HC 5х2 |

HC 5х5 |

| Technological parameters | |||

| Average product particle size when 0,8 mm grate is used, mm | 0,3-0,5 | 0,6-1,5 | |

| Comminuted product particle size when 0,8 mm grate is used, mm | 90%<0,5 | 90%<2,0 | |

| Maximum initial material grain size, mm* | 20 | 100 | |

| Mohs hardness of crushed material, up to | 4 | 5 | |

| Output, kg/hour* | 25-1500 | 100-3500 | 200-7000 |

| Technical parameters | |||

| Hopper loading door dimensions, mm | 200х330 | 260х490 | 220х495 |

| Crusher loading door dimensions, mm | 110х158 | 254х300 | 300х498 |

| Size of discharge grate openings, mm | 0,8-20 | 2-50 | |

| 50 Hz supply voltage, V | 380 | ||

| Electric motor power, kW | 2,2 | 11 | 22 |

| Rotor speed, rpm | 1500 | ||

| Overall dimensions (Length x Width x Height), mm |

885 х 550 х 1410 |

1560 х 805 х 1230 |

1755 х 840 х 1185 |

| Weight/weight with control panel, kg |

120/125 |

580/585 |

750/755 |

| Hammers material – tool steel | 66Mn4 | ||

| Hammers hardness, HRC | 52-56 | 38-42 | |

| Compatible control panel | MCP3-04 | MCP3-09 | MCP3-10 |

* Depends on the physical properties of the material and the size of discharge grate openings

Advantages of VIBROTECHNIK Hammer crushers:

- The ability to obtain various crushed product grain sizes by:

- installing grates with openings of various shapes and sizes from 0.8 mm;

- selecting the number and shape of the hammers;

- changing the HC 2х2 rotor rpm;

- installing a smooth or ribbed liner in the cover of the HC 2х2;

- Free suspension of the hammers on the rotor axes reduces the probability of mill breakage when an unbreakable object falls into the working chamber;

- The size and configuration of the loading funnel have been selected for safe maintenance and to prevent ejection of material particles during operation;

- The hinged bolts on the cover of the HC 2х2 provide quick access to the crushing chamber for inspection and replacement of hammers and grates, and cleaning

of the chamber; - Ability to connect to the dust collector to:

- lower the temperature in the crushing chamber;

- lower the content of the dust fraction in the product;

- separate material into three fractions: sedimented into the crusher receiving container, cyclone and bag filter.

- Equipment of the HC 5х2 and HC 5х5 with a support frame and receiving containers of various volumes depending on the process task.

Applications: сoal, foil, polyester resin, glass, slag, salt, shale, electrical circuits, HHD disks, food products.

Industries: mining, metallurgical, construction, chemical, pharmaceutical.