Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

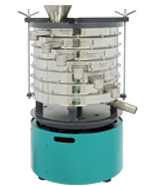

Circular Vibratory Screeners

The Circular Vibratory Screeners are designed for sieving bulk materials according to particle size classes.

The operating principle of the Circular Vibratory Screeners is similar to the operating principle of the analyzer, except that supply of the material to be sieved and discharge of the separate classes from the surface of the sieve and tray are continuous.

|

Characteristics |

CVS 30 |

CVS 40 |

CVS 50 |

|

| Inner frame diameter, mm | 300 | 400 | 500 | |

| Maximum number of sieves | 5 | 12 | 10 | 8 |

| Mesh size, mm |

0,315-2,8 | 0,315-5,0 | 0,315-5,0 | |

| Size of apertures in perforated plate, mm | 0,8-3,0 | 0,8-5,0 | 0,8-5,0 | |

| Maximum particle size of the material up to, mm | 5 | 7 | 7 | |

| Model of the vibration drive used | ||||

| VD 30, VD 30T | + | - | - | - |

| EVD | - | - | - | - |

| VD 50 | - | + | + | + |

| Vibration frequency, vibrations/minute | ||||

| VD 30, VD 30T | 1500 | - | - | - |

| EVD | - | - | - | - |

| VD 50 | - | 1500 | 1500 | 1500 |

| Amplitude of vibrations (depending on weight of sample and number of sieves), mm | ||||

| VD 30, VD 30T | 0,25-0,75** | - | - | - |

| EVD | - | - | - | - |

| VD 50 | - | 0,5-1,5** | 0,5-1,5** | 0,5-1,5** |

| 50 Hz supply voltage, V | 220 | 220/380 | 220/380 | 220/380 |

| Length (diameter), up to, mm | 390 | 576 | 576 | 721 |

| Width, up to, mm | 350 | - | 592 | 585 |

| Height, up to, mm | 550 | 1155 | 1305 | 1100 |

| Weight, up to, kg |

||||

| VD 30, VD 30T | 28 | - | - | - |

| EVD | - | - | - | - |

| VD 50 with control panel | - | 91 | 157 | 163 |

**Depends on the weight of the elements installed on the platform and the weight of the sample

Advantages of Circular Vibratory Screeners units:

- The distance traveled by the material particles during screening exceeds the diameter of the sieves installed, which improves sieving efficiency;

- Dust discharge is eliminated;

- The Circular Vibratory Screeners is equipped with corrugated discharge hoses and plastic receiving containers;

- Efficient screening using reciprocating helical vibrations of platform;

- Supply of elastic discharge hoses that do not distort the vibrations, for connecting pipes to receiving containers.

Advantages of CVS units with VF:

- Uniform feed of material to upper sieve of Screener;

- The material feed rate is adjusted by:

- moving the slide gate in the feed hopper;

- changing the amplitude of the feed tray vibrations making it possible to change the thickness of the material layer in the tray.

- Sealed connection of feeder, sieving elements and receiving containers;

- Efficient screening using reciprocating helical vibrations of platform;

- Increased output of Circular Vibratory Screeners CVS 40 and CVS 50 through simultaneous loading of material into several identical sieves on one sieving column.