Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

Circular Vibratory Screener CVS 40

|

INDUSTRIES

|

APPLICATIONS Diamonds, ferroalloys, ore, metal powders, coal, glass, ceramics, polymers, peat, cereals, coffee.

|

CHARACTERISTICS

|

PARAMETERS |

VALUES |

| Inner frame diameter, mm | 400 |

| Maximum number of sieves | 10 |

| Mesh size, mm |

0,315-5,0 |

| Size of apertures in perforated plate, mm | 0,8-5,0 |

| Maximum particle size of the material up to, mm | 7 |

| Model of the vibration drive used | |

| Vibration frequency, vibrations/minute |

1500 |

|

Amplitude of vibrations (depending on weight of sample and number of sieves), mm |

0,5-1,5** |

|

50 Hz supply voltage, V |

220/380 |

| Length (diameter), up to, mm |

576 |

| Width, up to, mm |

592 |

| Height, up to, mm |

1305 |

| Weight, up to, kg |

157 |

ADVANTAGES

|

CONTINUOUS SIEVING The use of screener sieves with discharge nozzles and bumpers provides continuous sieving of the material and its unloading in external receiving containers. |

|

|

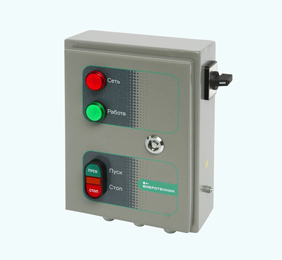

COMPATIBLE WITH CONTROL PANEL The control panel is designed to start and stop the equipment and provides:

Control panel with a timer can be ordered. |

|

DESCRIPTION OF THE DEVICE

|

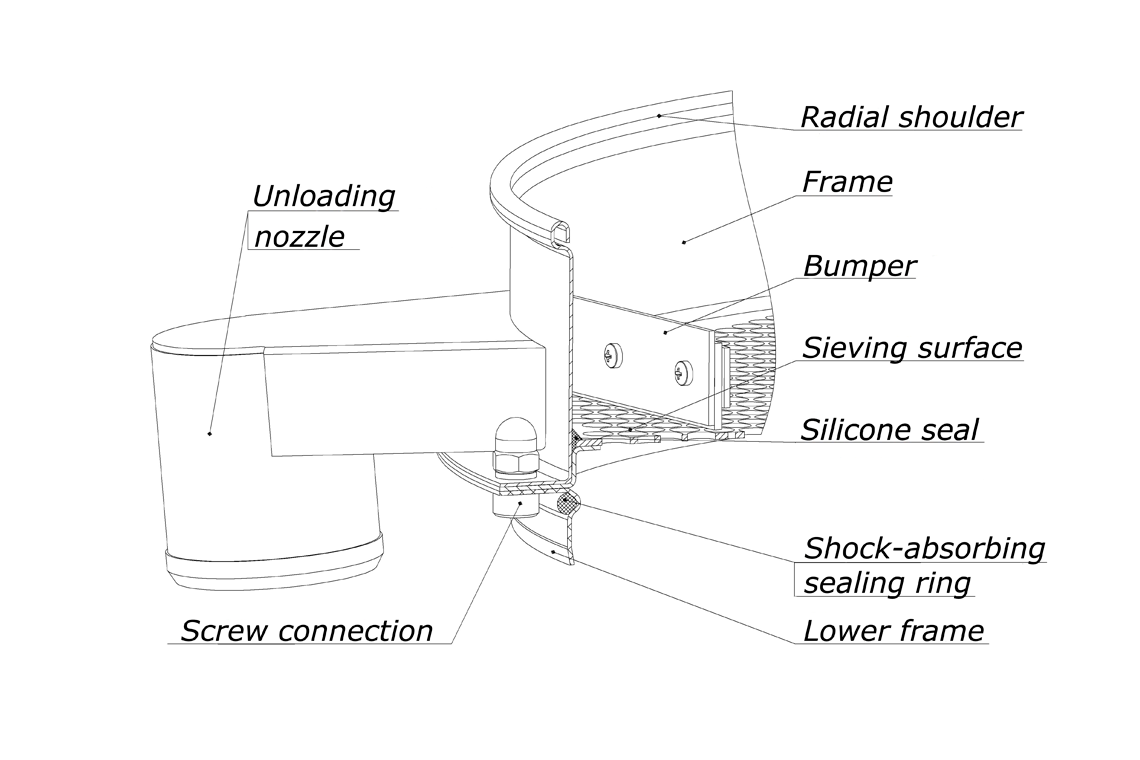

Circular vibratory screener includes: a vibration drive, a sieving part (consisting of a set of sieves complete with cover and tray) and a sieve fastener. The setup of the vibration drive is described in the corresponding section of the «Vibration drives» page. The set of screener sieves is fixed on the platform of the vibration drive using sieve fastener. CVS 40 screener sieve consists of upper and lower frame and a sieving surface made of metal mesh or perforated plate. A window in the frame and a discharge nozzle are provided for unloading the oversize product. To direct the flow of material particles into the window, a bumper inside the sieve is mounted. OPERATING PRINCIPLE The sieving of the material is carried out using one or more screener sieves, tray and cover. The number of sieves, as well as the mesh size or the size and shape of the apertures of the perforated plate are determined by the conditions of the analysis. To increase the sieving efficiency, the Circular vibratory screener can be equipped with intermediate trays. This allows installing multiple sets of sieves in one column. The material to be sieved is loaded into the upper sieve through the funnel, the nozzle or the membrane of the cover. The sieve column complete with tray and cover must be shaken using a VD 50 vibration drive. Using the vibration drive allows to increase productivity of sieving due to high-frequency reciprocating screw oscillations of the platform on which the column of sieves is fixed. Particles of material which are smaller than the size of the sells / apertures in the sieving surface of the upper sieve fall through on the next sieve, where the cycle repeats; larger particles move along the surface of the screening element and, due to the bumper, fall into the nozzle and are unloaded from the sieve into the receiving containers. As a result, the material is distributed in the receiving containers in accordance with the fractional content. |

Screener sieve with loading and discharge nozzles CVS 40 sieve scheme |

.png)

.png)

.png)