Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

Jaw crusher JC 15

|

INDUSTRIES

|

APPLICATIONS Ferroalloys, ores, slags, granite, marble, limestone, coal, coke, glass, ceramics.

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

|

Average product particle size at minimum gap, mm |

0,5-0,8 |

|

Product particle size at minimum gap, mm |

90%<1,0 |

| Maximum initial material grain size, mm* |

110 |

|

Mohs hardness of crushed material, up to |

7 |

|

Output, kg/hour* |

50-1500 |

|

TECHNICAL PARAMETERS |

|

|

Hopper loading door dimensions, mm |

160х245 |

|

Crusher loading door dimensions, mm |

150х250 |

|

Discharge slot adjustment range, mm |

1-40 |

|

50 Hz supply voltage, V |

380 |

|

Electric motor power, kW |

5,5 |

|

Gross/usable capacity of the collecting container, l |

14/9 |

|

Overall dimensions (Length x Width x Height / Height with support stand), mm |

1000х570х960 |

|

Weight/weight with support stand and control panel, kg |

520/ - |

|

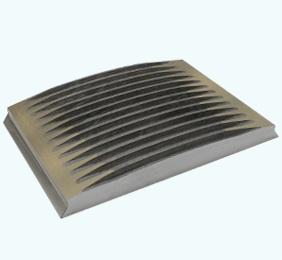

Jaw material – iron / steel / tungsten |

EN-GJN-HV600 (XCr14) / GX120Mn13 / - |

| Jaw hardness – iron / steel / tungsten carbide |

52-55/ 31-32 HRC/ - |

| Armor lining material — tool steel |

66Mn4 |

| Armor lining hardness, HRC |

31-32 |

|

Compartible control panel |

* Depends on the hardness of the material and the discharge slot setting.

ADVANTAGES

|

EASY LOADING Loading hopper configuration eliminates material ejection. An opening for connecting a dust extraction system is made in the rear of the hopper. |

|

|

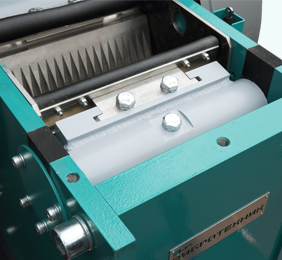

QUALITY SPARE PARTS The moving and fixed jaws of JC 15 are interchangeable, and can also be rotated 180 °. Lining armor made of wear-resistant steel. Bearings manufactured by the Swedish company SKF. |

|

COMPATIBILITY WITH ROTARY SAMPLE DIVIDER Simultaneous crushing and reduction due to the combination of JC 15 Jaw Crusher and RSD Rotary sample divider in a single technological complex. Aggregation eliminates the stage of sample overload, which reduces dusting and increases work productivity. |

|

DESCRIPTION OF THE DEVICE

|

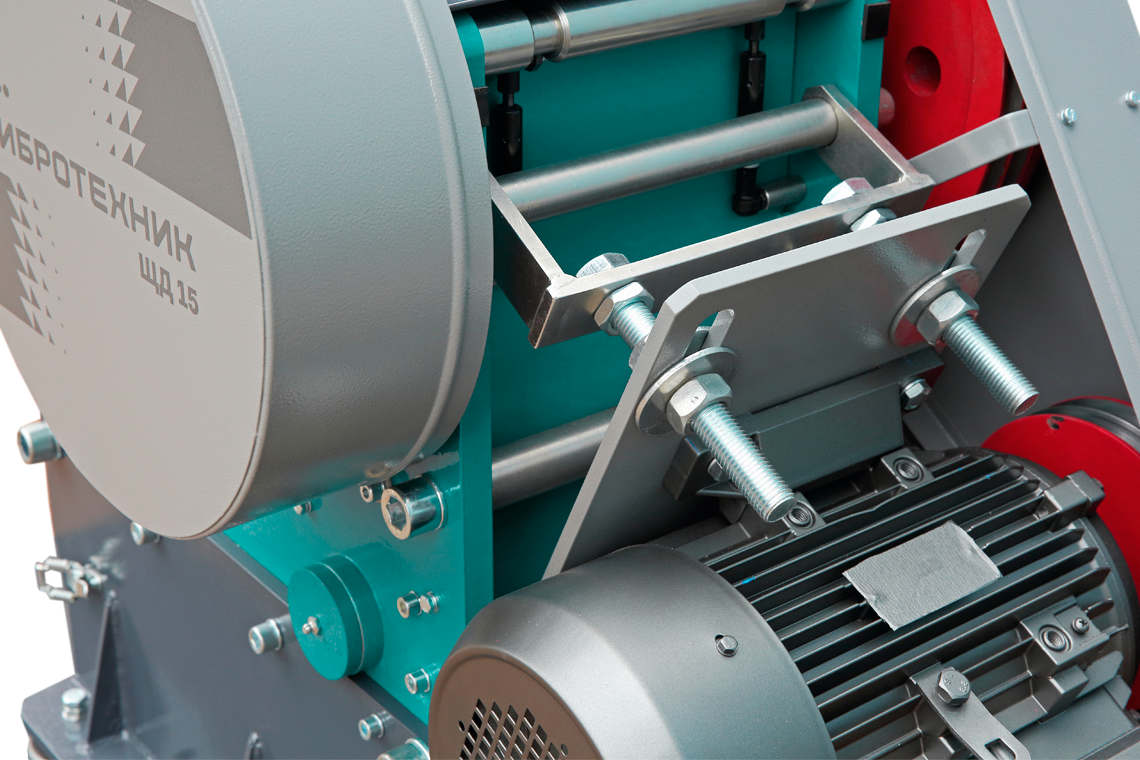

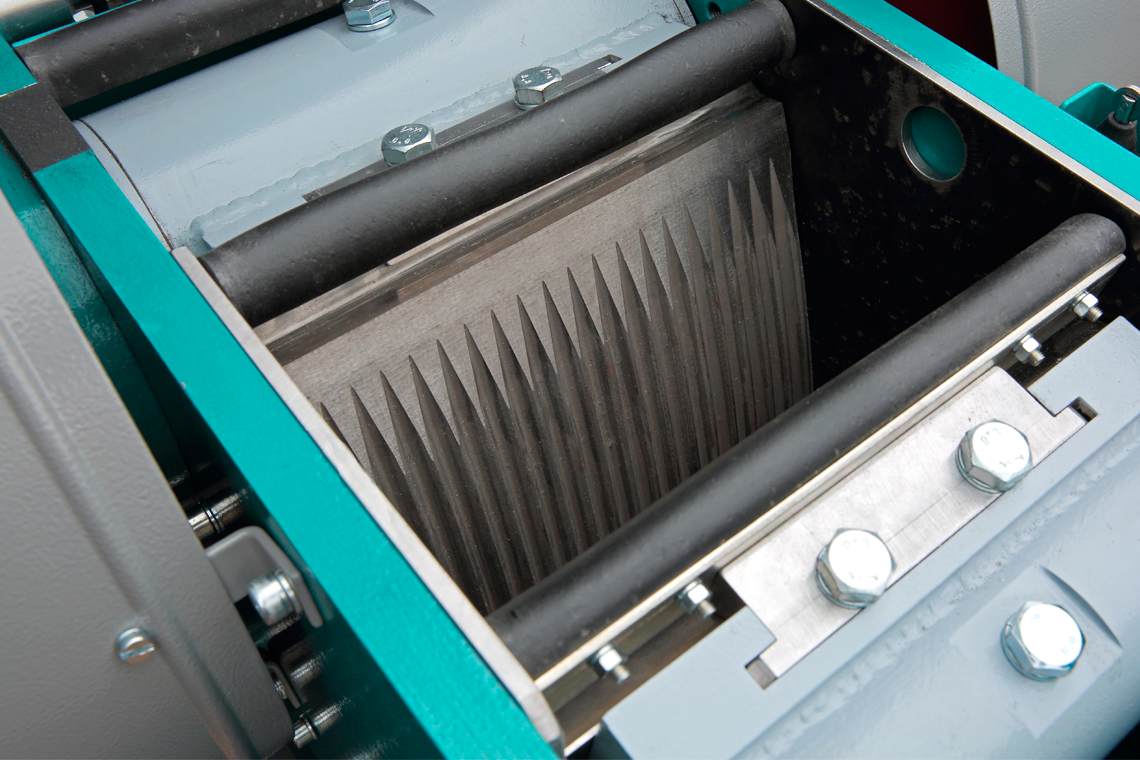

JC 15 is a jaw crusher with a complex movement of the jaw, the destruction of the material in which occurs due to compression and shear deformations. The size of the crushed material is determined by the gap between the jaws in the lower part (discharge gap) and the physical characteristics of the crushed material. The structure of the crusher includes: the loading hopper, the housing with the base mounted in, the connecting rod and the slot adjustment device. In the lower part of the housing there is a receiving container, in the back — the electric motor with a belt tensioner. Two jaws are located inside the housing: fixed one on the base and movable one on the connecting rod. The base is suspended on the axis, and its position in the lower part is determined by the adjusting device. The screw of the adjusting device rests against the base through the unit with Belleville springs, which protect the crusher from breaking if an invincible body enters. In the adjusting unit, a sawtooth thread of increased diameter S 36x3 is used, which reduces the danger of jamming of the device. Torque from the electric motor is transmitted through a belt drive to an eccentric shaft, on which a connecting rod with a movable jaw is mounted. The loading hopper has a configuration that eliminates material ejection from the crushing chamber. The hopper loading opening is closed by the lid. The hopper is mounted on the housing through a rotary axis and is fixed by two latches. The hopper is equipped with two gas lifts. In the lower part of the housing there is a nozzle for connecting the crusher to the dust collection system. The inner surface of the walls in the crushing zone is protected by lining armor made of wear-resistant steel. On the right side of the casing there is a bracket with the emergency stop button and the end switch that prevents the crusher from starting without a loading hopper. OPERATING PRINCIPLE Material is fed into the loading hopper, from where it enters the working space between the jaws. The upper smooth surface of the jaws is not involved in crushing. Middle surface is ribbed, which allows to increase the specific pressure on the particles of crushed material in the zone of preliminary crushing. The lower smooth lower surfaces of the jaws form a parallel zone — a zone of fine grinding, in which the product of the required particle size is obtained. The complex movement of the jaw (primary horizontal vibrations in the upper part of the crushing zone and vertical vibrations in the lower part) provides a high degree of crushing.

PRODUCTION OPTIONS

|

V-belt drive adjusting device JC 15 crushing zone JC 15 Jaw crusher and Cyclone dust collector with hood

MCP3 control panel

Loading scoops, V=1,2 L |