Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

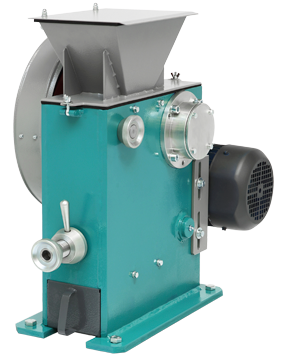

Jaw crusher JC 6

|

INDUSTRIES

|

APPLICATIONS Ferroalloys, ores, slags, granite, marble, limestone, coal, coke, glass, ceramics.

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

|

Average product particle size at minimum gap, mm |

0,5-1,0 |

|

Product particle size at minimum gap, mm |

90%<2,0 |

| Maximum initial material grain size, mm* |

50 |

|

Mohs hardness of crushed material, up to |

8** |

|

Output, kg/hour* |

25-400 |

|

TECHNICAL PARAMETERS |

|

|

Hopper loading door dimensions, mm |

160х250 |

|

Crusher loading door dimensions, mm |

60х100 |

|

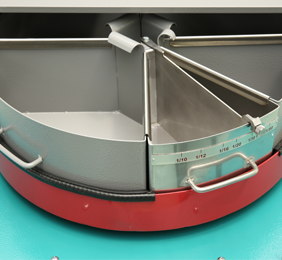

Discharge slot adjustment range, mm |

2-15 |

|

50 Hz supply voltage, V |

380 |

|

Electric motor power, kW |

1,1 |

|

Gross/usable capacity of the collecting container, l |

2,1/1,4 |

|

Gross/usable capacity of the collecting tank, l |

10/6,5 |

|

Overall dimensions (Length x Width x Height / Height with support stand), mm |

640х340х600 / 1090 |

|

Weight/weight with support stand and control panel, kg |

130/165 |

|

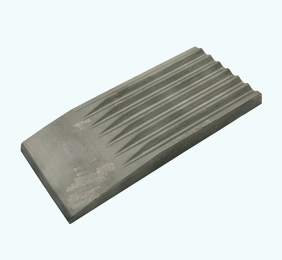

Jaw material – iron / steel / tungsten |

EN-GJN-HV600 (XCr14) / GX120Mn13 / tungsten carbide |

| Jaw hardness – iron / steel / tungsten carbide |

52-55/ 31-32 HRC/ 1180-1280 HV |

| Armor lining material — tool steel |

66Mn4 |

| Armor lining hardness, HRC |

31-32 |

|

Compartible control panel |

* Depends on the hardness of the material and the discharge slot setting.

** When using jaws made of tungsten carbide.

ADVANTAGES

|

COLLECTING CONTAINER Possibility of completing with a collecting container of 10 liters. |

|

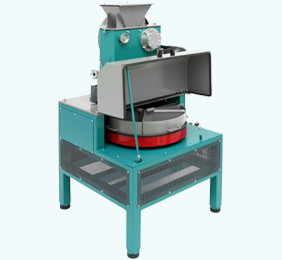

COMPATIBILITY WITH ROTARY SAMPLE DIVIDER Simultaneous crushing and reduction due to the combination of JC 6 Jaw Crusher and RSD Rotary sample divider in a single technological complex. Aggregation eliminates the stage of sample overload, which reduces dusting and increases work productivity.

|

DESCRIPTION OF THE DEVICE

|

JC 6 is a jaw crusher with a complex movement of the jaw, the destruction of the material in which occurs due to compression and shear deformations. The size of the crushed material is determined by the gap between the jaws in the lower part (discharge gap) and the physical characteristics of the crushed material.

The base is suspended on the axis, and its position in the lower part is determined by the adjusting device. The screw of the adjusting device rests against the base through the unit with Belleville springs, which protect the crusher from breaking if an invincible body enters.

OPERATING PRINCIPLE Material is fed into the loading hopper, from where it enters the working space between the jaws. The upper surface of the jaws is ribbed, which allows to increase the specific pressure on the particles of crushed material in the zone of preliminary crushing. The lower smooth lower surfaces of the jaws form a parallel zone — a zone of fine grinding, in which the product of the required particle size is obtained. With a rotating eccentric shaft, the movable jaw moves relative to the fixed one. The material is crushed when the jaws come together and unloaded when the movable jaw moves off. The crushing product is collected in a receiving container located under the discharge zone. PRODUCTION OPTIONS

SPECIAL OPTIONS:

|

JC 6 crushing zone JC 6 Jaw crusher and Cyclone dust collector with hood

MCP3 control panel

Loading scoops, V=1,2 L |