Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

Cutting mill CM 250

|

INDUSTRIES

|

APPLICATIONS Bismuth telluride, carbon fiber, polyester resin, ABS plastic, nanotubes, collagen, rubber, jute, PAN fiber, fabric, cotton, rubber, silicone, wax, bark, chicory, dried mushrooms, tea

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

| Average product particle size when installing a grate with minimum openings, mm | 0,4-1,0 |

| Product particle size when installing a grate with minimum openings, mm | 90%<2,0 |

| Maximum initial material grain size, mm* | 150 |

| Output, kg/hour** | 10-300 |

| TECHNICAL PARAMETERS | |

| Mill loading door dimensions, mm | 250х280 |

| Size of discharge grate openings, mm | 2-50 |

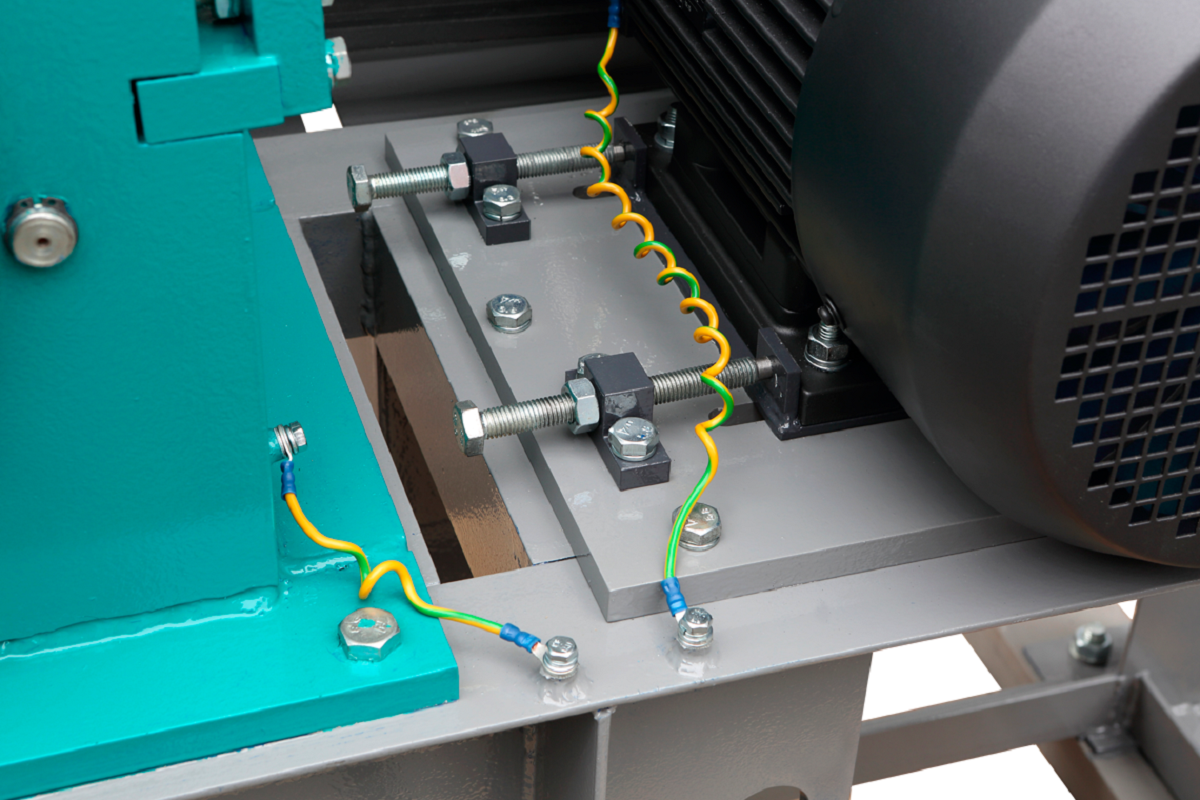

| 50 Hz supply voltage, V | 380 |

| Electric motor power, kW | 7,5 |

| Rotor speed, rpm | 1000 |

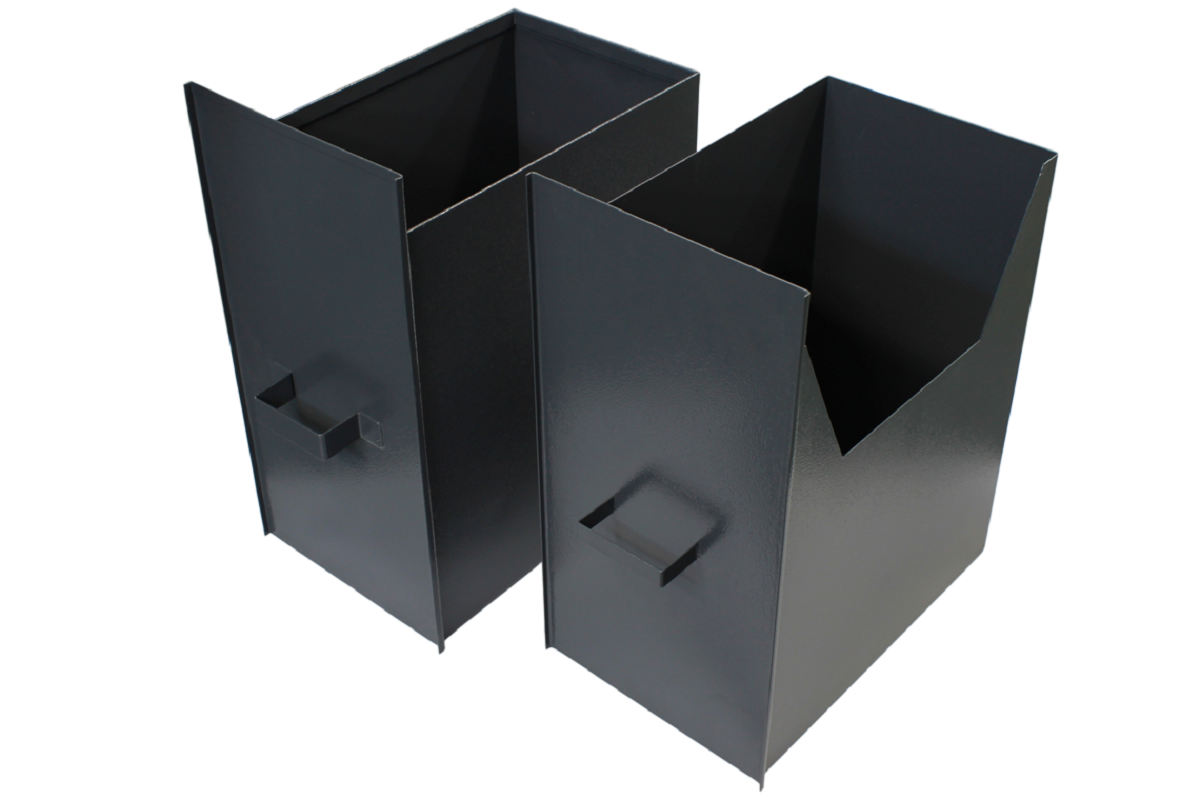

| Gross/usable capacity of the collecting container, l | 53/35 |

| Overall dimensions (Length x Width x Height), mm | 1525х585х1465 |

| Weight/weight with control panel, kg | 460/465 |

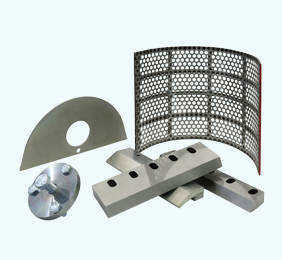

| Blades material – tool steel | 105WCr6, 90CrSi |

| Blades hardness, HRC | 40-45 |

| Compatible control panel | MCP3-11 |

* It is possible to batch load materials of an elongated shape, the size of which in one of the dimensions significantly exceeds the specified

** Depends on the physical properties of the material and the size of discharge grate openings

ADVANTAGES

|

COMPATIBLE WITH DUST СOLLECTOR Ability to connect to dust collector to:

|

|

DESCRIPTION OF THE DEVICE

|

In a cutting mill, comminution occurs due to cutting — shear deformations. The structure of CM 250 cutting mill includes: a frame, a housing, a loading hopper, a rotor, a folding support, a discharge grate, a collecting container and an electric motor. The mill with loading hopper is mounted on the frame. The main working body of the mill is the rotor, which has a three-beam shape. It has three moving blades. On the casing two fixed blades are mounted. In the lower part of the body there is a folding support with discharge grate. The size of grate openings determines the size of the product particles. Torque from the electric motor is transmitted through a belt drive. In the lower part of the frame the collecting container is installed. CM 250 cutting mill can be equipped for two unloading modes:

OPERATING PRINCIPLE The material fed through the loading funnel into the milling chamber. Milling (cutting) of the material occurs when particles enter between the casing blades and the rotor blades. The milled material passes through the openings of the discharge grate into collecting container. When cyclone dust collector is connected, small particles of the comminuted material are captured by the air flow. The air flow passes through the shutter into dust collector, where material is precipitated in the cyclone and air is filtered in the bag filter. PRODUCTION OPTIONS

SPECIAL OPTIONS:

|

CM 250 crushing chamber CM 250 collecting container V-belt drive adjusting device MCP3 control panel

Loading scoops, V=1,2 L |