|

APPLICATIONS

Asphalt concrete and sand-gravel mixes.

|

|

|

CHARACTERISTICS

|

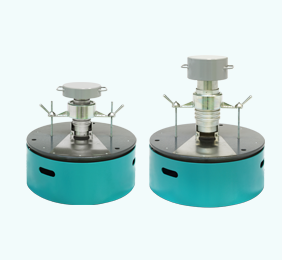

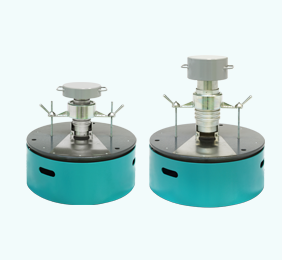

Vibration table VT with Ø71.4 mm mold

|

Vibration table VT with Ø101.4 mm mold

|

|

Mold inner diameter (mm)

|

Ø 71,4

|

Ø 101

|

|

Amplitude of vibrations under load (mm)

|

0,4±0,05

|

|

Vibration (vibrations/minute)

|

2900±100

|

|

Operating time (seconds)

|

180±5

|

|

Vertical load (kPa)

|

30±5

|

|

50 Hz supply voltage (V)

|

380

|

|

Number of electric motors

|

2

|

|

Electric motor power (kW)

|

2х0,25

|

|

Overall dimensions when assembled with molds, stamps and weight (Length x Width x Height) (mm)

|

550х550х520

|

550х550х660

|

|

Weight (kg)

|

140

|

156

|

ADVANTAGES

|

The Vibration table VT is designed for vibration compaction of specimens of asphalt concrete mixes during testing in accordance with State Standard 12801-98 «Materials Based on Organic Binders for Road and Airport Construction. Test Methods.»

|

|

The Vibration table VT is equipped with two types of molds: Ø71.4 mm for samples of fine-grained asphalt concrete and Ø101 mm for samples of coarse-grained asphalt concrete.

|

|

|

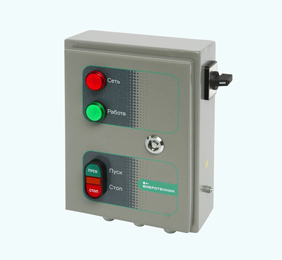

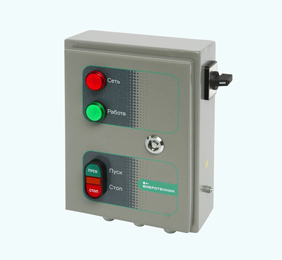

COMPATIBLE WITH CONTROL PANEL

The control panel is designed to start and stop the equipment and provides:

- automatic power off when exceeding the maximum current value or short circuit;

- protection of the operator from electric shock;

- motor overload protection.

Control panel with a timer can be ordered

|

|

The primary components of the product are the vibration drive, receptacle, mold with stamps and weights and control panel.

The weight of the Vibration table VT platform is selected so that the amplitude of the vibrations specified by the state standard is ensured when using both molds, without additional adjustments.

|

|

DESCRIPTION OF THE DEVICE

|

Advantages:

- The strictly vertical linear vibrations that ensure a stable position of the weights during operation and the load on the specimen specified by the state standard;

- The presence of a control panel with an integrated 3-minute timer;

- The amplitude of the vibrations specified by the state standard is ensured during operation with both molds without additional adjustments;

- Supply of lightweight molds;

- An additional receptacle for filling the molds with mix;

- Support stand.

|

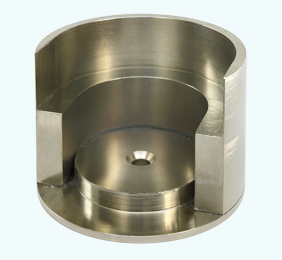

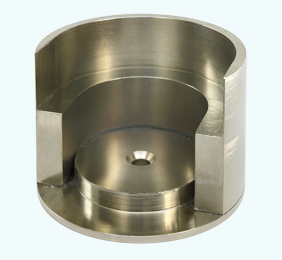

Socket, 2 punches, mold

T 70 stand

|