Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

Shaker mixer SM 50.0 «Drum Tumbler»

|

APPLICATIONS Food additives, thermoplastics, chemicals, sand, slag

|

CHARACTERISTICS

|

PARAMETERS |

VALUES |

|

Technical characteristics |

|

| Gross/usable capacity of the drum, l | 50/ 33 |

| Cup/drum rotation speed, rpm | 49 |

| 50 Hz supply voltage, V | 380 |

| Motor-reducer power, kW | 0,75 |

| Overall dimensions (Length x Width x Height), mm | 1155х770х1000 |

| Weight/weight with control panel, kg | -/134 |

| Cup/drum and lid material | AISI 304 |

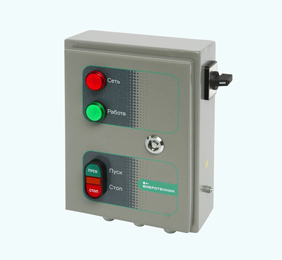

| Compatible control panel | MCP3-01 |

ADVANTAGES

|

COMPATIBLE WITH CONTROL PANEL The control panel is designed to start and stop the equipment and provides:

Control panel with a timer can be ordered. |

|

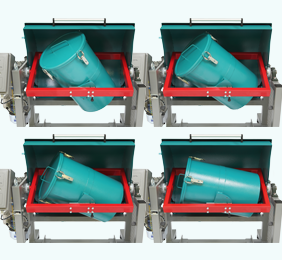

FOUR OPERATING MODES Adjustable tilt angle of drum relative to its axis of rotation (15, 30, 45 or 60°). |

|

|

LOADING AND UNLOADING POSITIONS For loading and unloading the material, the drum is fixed at an angle of 90° to the frame. |

|

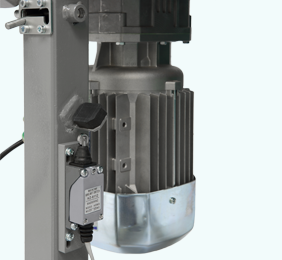

QUALITY SPARE PARTS Drum and lid are made of stainless steel (AISI 321). SM 50.0 shaker mixer is equipped with Bonfiglioli gear motor. The frame is mounted on a floating bearing. |

|

DESCRIPTION OF THE DEVICE

|

The mixing of the components in the mixer takes place in a drum fixed at an angle in a rotating frame. The structure of the mixer includes: a body, a frame, a drum, a receiving container, a casing and a gear motor. When the mixer is operating the frame with the barrel fixed in it rotates around its axis, which ensures mixing of the material. The mixer has a low rotation speed to avoid grinding and destruction of particles during mixing. Principle of operation In the upper part of the body there is a gear motor, which rotates a rectangular frame with a drum. The drum is mounted to the frame through the fixing unit in such a way that the angle of drum relative to its axis of rotation can be 15, 30, 45 and 60°. The mixer provides as well an angle of 90° for loading and unloading of the material. |

Drum, lid and latch Sector and drum lock |

.png)

.png)