Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

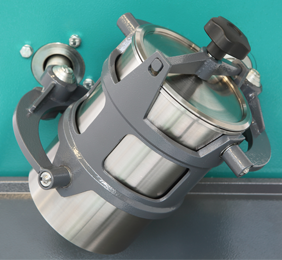

Shaker mixer SM 2.0

|

APPLICATIONS Food additives, thermoplastics, chemicals, sand, slag

|

CHARACTERISTICS

|

PARAMETERS |

VALUES |

| Gross/usable capacity of the cup, l | 2,6/ 1,7 |

| Gross/usable capacity of the drum, l | - |

| Cup/drum rotation speed, rpm | 10 — 55 |

| 50 Hz supply voltage, V | 220 |

| Motor-reducer power, kW | 0,18 |

| Overall dimensions (Length x Width x Height), mm | 610х525х430 |

| Weight/weight with control panel, kg | 100/- |

| Cup/drum and lid material | AISI 304 |

| Compatible control panel | built-in control panel |

ADVANTAGES

|

DIGITAL CONTROL PANEL The digital panel allows setting the operating time and frequency of rotation of the cup. |

|

TWO TYPES OF CUPS SM 2.0 shaker mixer can be equipped with stainless steel or glass cup. |

|

|

QUALITY SPARE PARTS The mixing cup is made of stainless steel AISI 321 or glass. |

DESCRIPTION OF THE DEVICE

|

The structure of the mixer includes: a casing, a cup, a basket, a cover, a control panel and a motor reducer. The mixing of the components in the mixer takes place in a bowl that performs complex spatial movements. SM 2.0 shaker mixer consists of two parts: an actuator located in the front, and drive and control units located in the back. The actuator is closed with a transparent cover. The closed cup into which the mixed components are poured is fixed in the basket. The operating mode of the motor reducer (cup rotation speed) and the required operating time are set using the control panel. OPERATING PRINCIPLE When the mixer is turned on and the program is selected, the motor reducer rotates the drive shaft, which transmits torque to the basket with the cup. PRODUCTION OPTIONS

|

SM 2.0 shaker mixer with stainless steel cup SM 2.0 shaker mixer with glass cup SM 2.0 shake mixer on T 70 stand Loading scoops, V= 0,07 L and 1,2 L |

.png)

.png)

.png)