Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

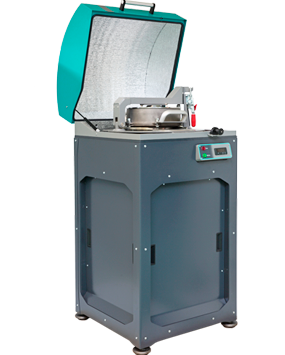

Vibrating grinder VGE

|

INDUSTRIES

|

APPLICATIONS Ferroalloys, slag, coke, glass, soda, mineral fertilizers, granite, marble, cement, soil.

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

| Average product particle size, mm | 15-25 |

| Minimum product particle size, mm | 90%<40 |

| Maximum initial material grain size, mm | 20 |

| Loading volume of one cup, cm3 | 250-750 |

| Grinding time, min | 1-30 |

| Mohs hardness of comminuted material, up to | 7 |

| TECHNICAL PARAMETERS | |

| Number of cups | 1 |

| 50 Hz supply voltage, V | 380 |

| Electric motor power, kW | 2,2 |

| Vibration frequency, vibrations/minute | 1000 |

| Vibration amplitude, mm | 16 |

| Overall dimensions (Length x Width x Height), mm | 670х615х1225 |

| Weight/weight with control panel, kg | 350/- |

| Grinding elements material – tool steel/zirconium dioxide/tungsten carbide | HARDOX 500Q,X20Cr13/-/- |

| Grinding elements hardness – tool steel/zirconium dioxide/tungsten carbide | 52-55, 40-48 HRC/-/- |

| Compatible control panel | built-in timer |

VGE is not intended for grinding of humid, greasy or prone to agglomeration materials.

ADVANTAGES

|

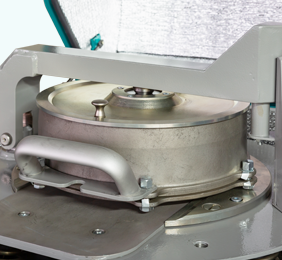

WIDE RANGE OF SAMPLE VOLUMES There is a possibility of grinding samples from 250 to 750 ml in a standard cup. |

|

|

BUILT-IN TIMER The timer allows setting the operating time and automatically stops the grinder. |

|

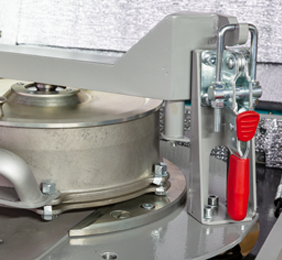

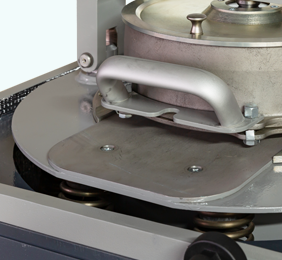

SAFE CUP FIXATION The cup fastener is equipped with a locking latch that excludes spontaneous opening of the cup. |

|

CONVENIENT SAMPLE UNLOADING The cup lifting device and the hook for the roller provide the operating convenience. |

|

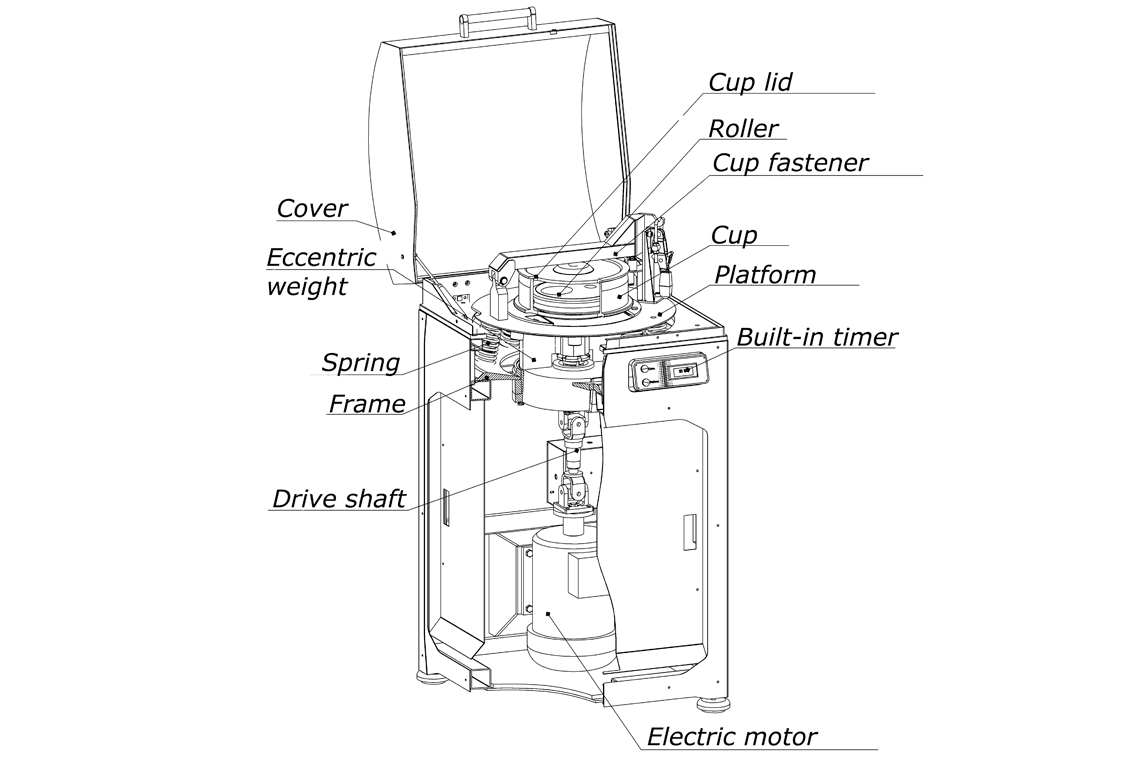

DESCRIPTION OF THE DEVICE

|

In VGE vibrating grinder comminution occurs due to abrasion — simultaneous compression and shear of the material. The product particle size depends on the hardness of the material and the comminution time. The platform with the cup fastener fixed on it and assembled cup (cup itself, lid and roller) is mounted on the frame through the springs. The torque from the electric motor is transmitted through the drive shaft to the eccentric weight on the axis of the platform. The folding cover of VGE is designed to insulate the noise and to prevent access to the vibrating parts of the grinder. OPERATING PRINCIPLE VGE platform with the cup fixed on it performs circular oscillations in the horizontal plane. Due to this, the roller makes circular movements along the walls of the cup. The material is grinded between the roller, the bottom and the walls of the cup. The built-in timer allows to set the comminution time in the range from 1 to 30 minutes. The time needed is to be determined empirically and depends on the material hardness and the volume of the sample. |

VGE scheme Loading scoops, V=1,2 L |

.png)

.png)