Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

Vibrating grinder VG 1

|

INDUSTRIES

|

APPLICATIONS Ferroalloys, slag, coke, glass, soda, mineral fertilizers, granite, marble, cement, soil.

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

| Average product particle size, mm | 20-30 |

| Minimum product particle size, mm | 90%<50 |

| Maximum initial material grain size, mm | 10 |

| Loading volume of one cup, cm3 | 20-50 |

| Grinding time, min | 1-30 |

| Mohs hardness of comminuted material, up to | 8* |

| TECHNICAL PARAMETERS | |

| Number of cups | 1 |

| 50 Hz supply voltage, V | 380 |

| Electric motor power, kW | 0,37 |

| Vibration frequency, vibrations/minute | 1500 |

| Vibration amplitude, mm | 3,5 |

| Overall dimensions (Length x Width x Height), mm | 509x395x310 |

| Weight/weight with control panel, kg | -/59 |

| Grinding elements material – tool steel/zirconium dioxide/tungsten carbide | 105WCr6 or 90CrSi/ZrO2/- |

| Grinding elements hardness – tool steel/zirconium dioxide/tungsten carbide | 58-62 HRC/ 1200-1250 HV/- |

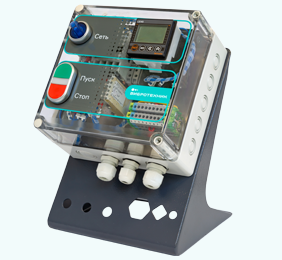

| Compartible control panel | PCP3-03 (with the timer) |

* When using grinding elements made of zirconium dioxide or tungsten carbide

ADVANTAGES

|

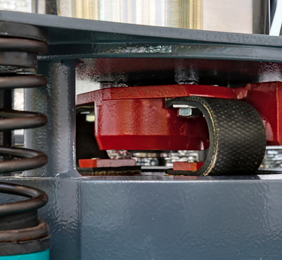

ORIGINAL DRIVE SYSTEM The use of elastic lobe clutch reduces the vibration transmitted to the bearing surface. |

|

|

NO SAMPLE CONTAMINATION The use of zirconium dioxide cup allows avoiding the contamination of the sample by metal particles of the grinder working bodies. |

|

|

COMPATIBLE WITH CONTROL PANEL The control panel is designed to start and stop the equipment and provides:

|

DESCRIPTION OF THE DEVICE

|

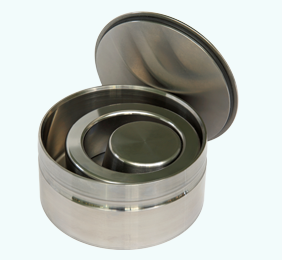

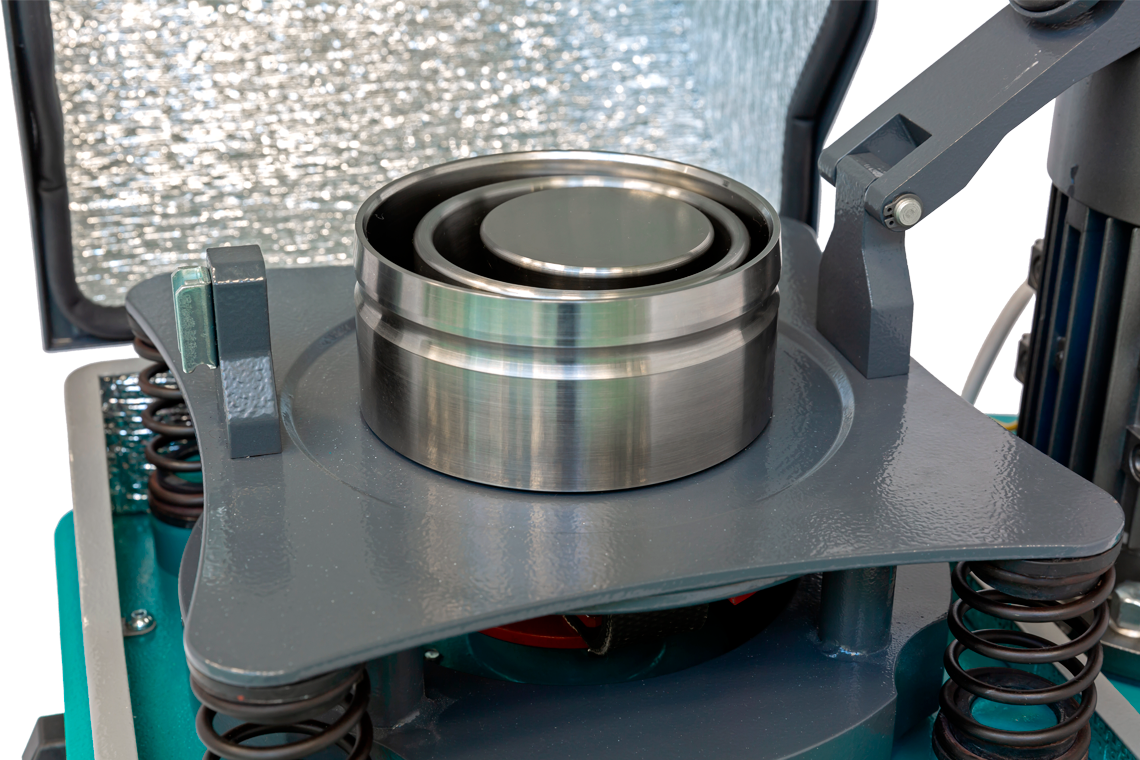

In VG 1 vibrating grinder comminution occurs due to abrasion — simultaneous compression and shear of the material. The product particle size depends on the hardness of the material and the comminution time. A platform with a cup fastener and a cup assembled (a cup, a lid, a ring, a roller) is mounted on the platform through the springs. Rotation from the electric motor is transmitted through a belt drive to a drive shaft, which is mounted on a plate in the bearing assembly. From drive shaft the torque is transmitted through an elastic lobe clutch coupling to the debalance fixed on the axis of the platform. The folding cover of VG 1 is designed to insulate the noise and to prevent access to the vibrating parts of the grinder. OPERATING PRINCIPLE VG 1 platform with the cup fixed on it performs circular oscillations in the horizontal plane. Due to this, the ring runs on the walls of the cup, and the roller — on the walls of the ring. The material is grinded between the walls of the cup and the ring, between the roller and the ring, and also between the lower ends of the roller, ring and the bottom of the cup; the upper ends of the ring, roller and lid. |

VG 1 cup, roller and ring Loading scoops, V=0,7 L T 70 stand |

.png)

.png)