Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

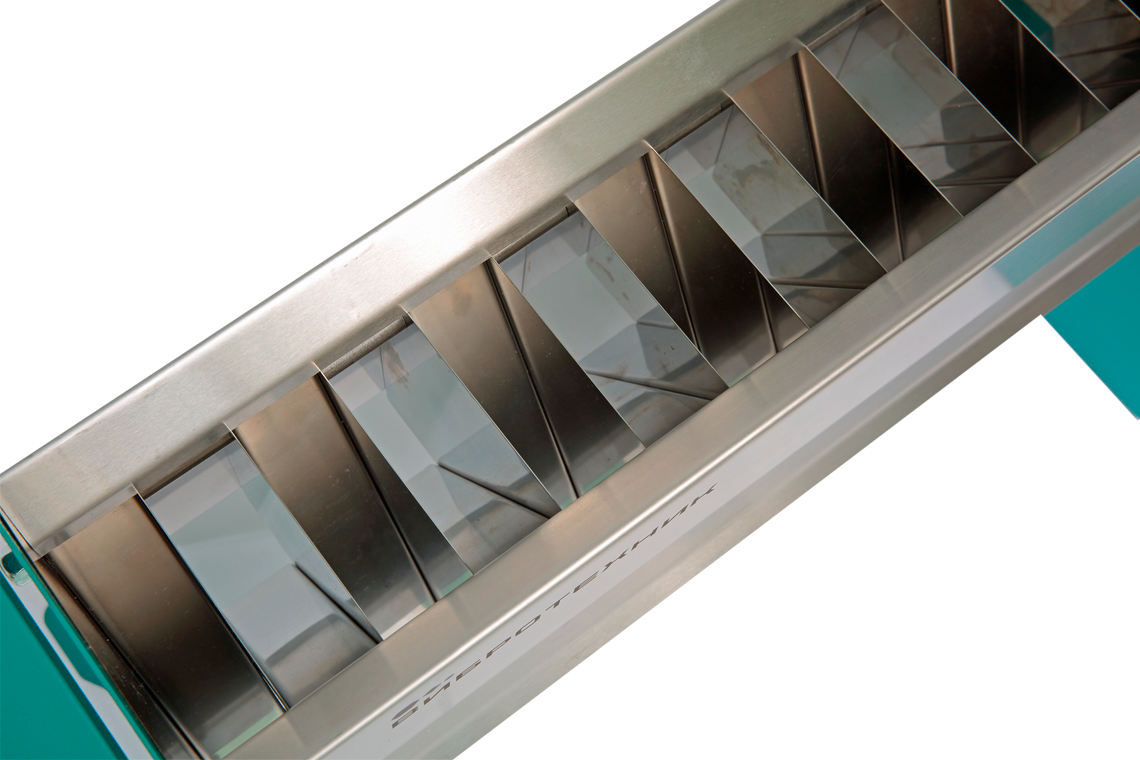

Riffle sample splitter RSS 37,5

|

INDUSTRIES

|

APPLICATIONS Any dry bulk materials: ferroalloys, ores, granite, soil, sand, coal, glass.

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

| Maximum material feed size, mm | 20 |

| TECHNICAL PARAMETERS | |

| Riffle width, mm | 37,5 |

| Number of riffles | 14 |

| Gross/usable capacity of the sample collector, l | 17,5/ 12,5 |

| Overall dimensions with 2 sample collectors (Length x Width x Height), mm | 600х546х403 |

| Overall dimensions of 3rd sample collector (Length x Width x Height), mm | 510х270х261 |

| Weight, including 3rd sample collector, kg | 26,5 |

| Material of splitting unit and sample collectors | AISI 304 |

ADVANTAGES

DESCRIPTION OF THE DEVICE

|

The structure of the riffle sample splitter includes: a splitting unit, sidewalls, racks, three sample collectors. The splitting unit is a package of plates forming riffles directed alternately to the sides. The block is covered by casing with loading funnel in the upper part. Samplers are designed to collect a divided sample for uniform loading of the sample over the entire width of the loading funnel. OPERATING PRINCIPLE The riffle sample splitter must be placed horizontally on a flat surface. Samplers should be inserted under the splitting unit until they stop. The sample is fed to a loading funnel. The material enters the splitting unit and is evenly distributed along the riffles to the sample collectors. Parts of the sample are transferred for further processing or re-division. |

Splitter riffles T 70 stand |

.png)

.png)

.png)