Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

Hammer crusher HC 2x2

|

INDUSTRIES

|

APPLICATIONS Coal, foil, polyester resin, glass, slag, salt, automotive catalyst, mica, electrical circuits, food products.

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

| Average product particle size when 0,8 mm grate is used, mm | 0,3-0,5 |

| Comminuted product particle size when 0,8 mm grate is used, mm | 90%<0,5 |

| Maximum initial material grain size, mm* | 20 |

| Mohs hardness of crushed material, up to | 4 |

| Output, kg/hour* | 25-1500 |

| TECHNICAL PARAMETERS | |

| Hopper loading door dimensions, mm | 200х330 |

| Crusher loading door dimensions, mm | 110х158 |

| Size of discharge grate openings, mm | 0,8-20 |

| 50 Hz supply voltage, V | 380 |

| Electric motor power, kW | 2,2 |

| Rotor speed, rpm | 1500 |

| Overall dimensions (Length x Width x Height), mm |

885 х 550 х 1410 |

| Weight/weight with control panel, kg |

120/125 |

| Hammers material – tool steel | 66Mn4 |

| Hammers hardness, HRC | 52-56 |

| Compatible control panel | MCP3-04 |

* Depends on the physical properties of the material and the size of discharge grate openings

ADVANTAGES

|

COMPATIBLE WITH DUST СOLLECTOR Ability to connect to dust collector to:

|

DESCRIPTION OF THE DEVICE

|

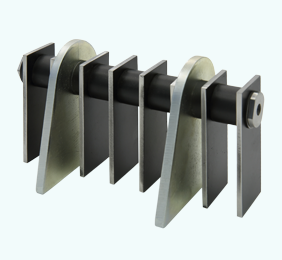

The principle of operation of the hammer crusher is based on the impact on particles of material. The structure of HC 2x2 Hammer crusher includes: loading hopper, lid, base, rotor, electric motor and support stand. The milling chamber is formed by the inner surface of the lid, part of the base and the discharge grate installed in the base. A rotor (shaft on which two discs) is mounted inside the milling chamber. Six axes with hinged hammers are inserted into the holes made on the periphery of the disks. A loading hopper is installed on the lid. Inside the hopper there are a curtain and two bumpers. A window is provided in the side wall of the housing for connecting the dust collector. Torque from the electric motor is transmitted through a belt drive to the rotor. OPERATING PRINCIPLE The initial material is fed through the loading hopper into the milling chamber, where it is destroyed by hammers, impacts and friction on the inner surfaces of the milling chamber, and is also self-grinding. The milled material passes through the openings of the discharge grate, the size of which determines the size of the product particles, and enters the receiving container and / or is transported by the air flow to the cyclone and bag filter of the dust collector. The hammers are thin rectangular steel plates. The sides of the hammers can be either flat or sharpened at different angles. The number and shape of hammers is determined by the assigned technological task. PRODUCTION OPTIONS

SPECIAL OPTIONS:

|

MCP3 control panel Loading scoops, V=1,2 L HC 2x2 hammer crusher with dust collector |

.png)