Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

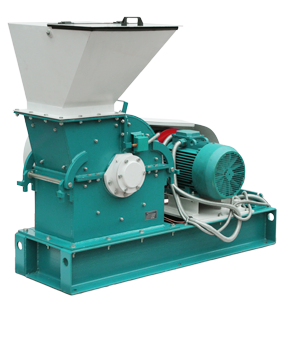

Hammer crusher HC 5X2

|

INDUSTRIES

|

APPLICATIONS Coal, foil, polyester resin, glass, slag, salt, automotive catalyst, mica, electrical circuits, food products.

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

| Average product particle size when 0,8 mm grate is used, mm | 0,6-1,5 |

| Comminuted product particle size when 0,8 mm grate is used, mm | 90%<2,0 |

| Maximum initial material grain size, mm* | 100 |

| Mohs hardness of crushed material, up to | 5 |

| Output, kg/hour* | 100-3500 |

| Technical parameters | |

| Hopper loading door dimensions, mm | 260х490 |

| Crusher loading door dimensions, mm | 254х300 |

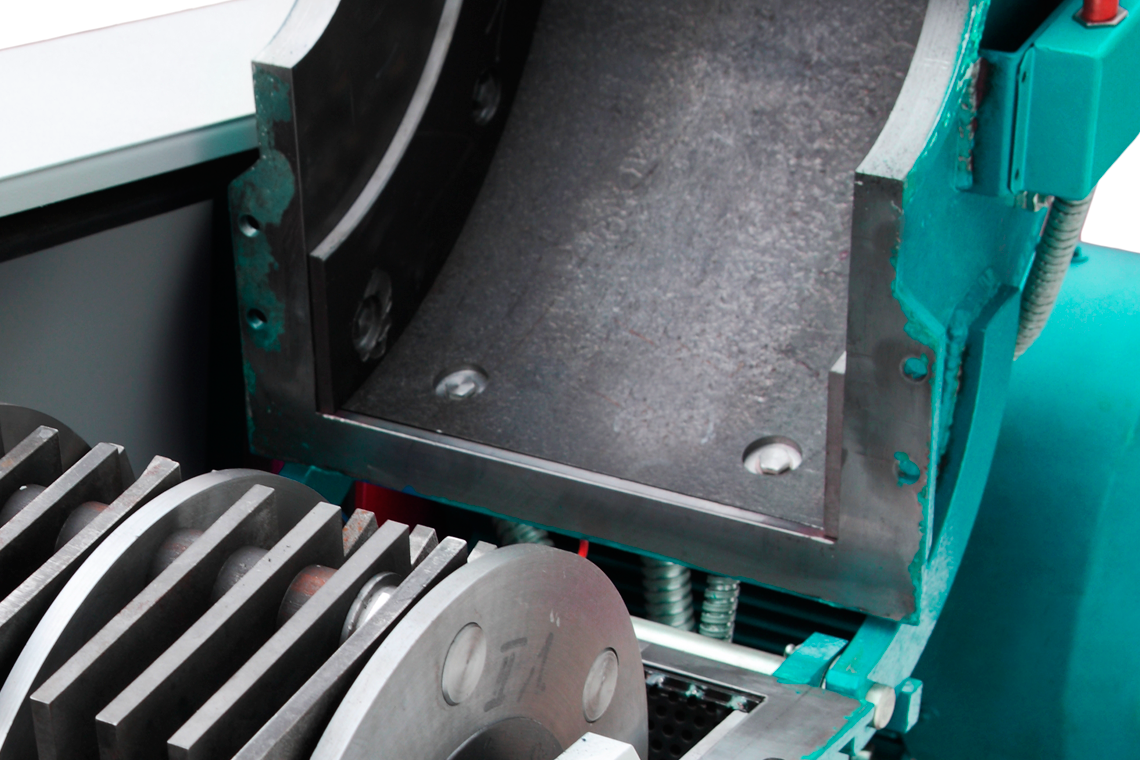

| Size of discharge grate openings, mm | 2-50 |

| 50 Hz supply voltage, V | 380 |

| Electric motor power, kW | 11 |

| Rotor speed, rpm | 1500 |

| Overall dimensions (Length x Width x Height), mm |

1560 х 805 х 1230 |

| Weight/weight with control panel, kg |

580/585 |

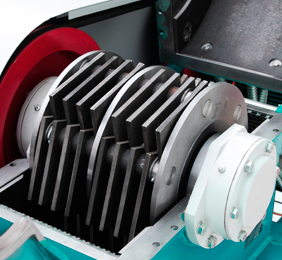

| Hammers material – tool steel | 66Mn4 |

| Hammers hardness, HRC | 38-42 |

| Compatible control panel | MCP3-09 |

* Depends on the physical properties of the material and the size of discharge grate openings

ADVANTAGES

|

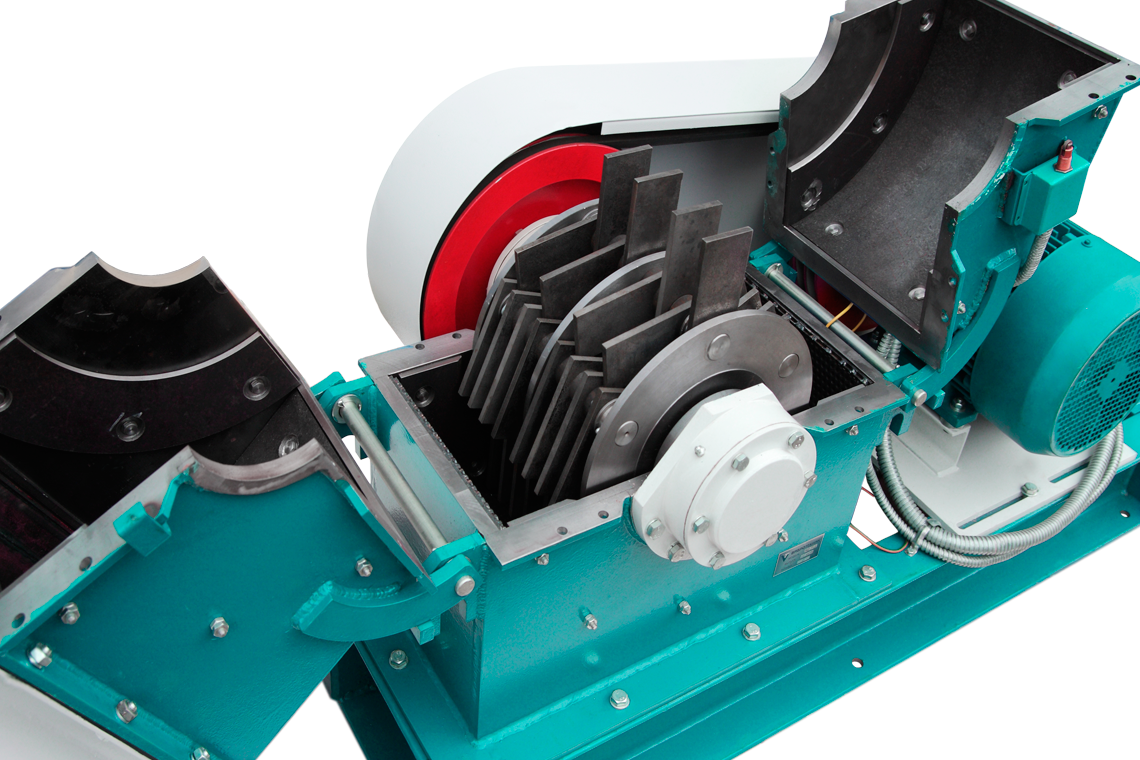

MILLING EFFICIENCY Particles of the material are destroyed by the hammers impacts and friction on the inner surfaces of the crushing chamber, as well as self-grinding. PRODUCT PARTICLE SIZE AJUSTMENT There are 3 ways to adjust the particle size of the product:

EASY MAINTENANCE Hinged covers provide quick access to the milling chamber for inspection and replacement of hammers and grates, and cleaning of the chamber. OPERATIONAL SAFETY The size and configuration of the loading hopper preclude access to the milling chamber. A curtain in the hopper excludes the material ejection from the milling chamber. The end switch excludes start-up with open milling chamber. All rotating parts and assemblies are covered by the casing. |

|

COMPATIBLE WITH DUST СOLLECTOR Ability to connect to dust collector to:

|

DESCRIPTION OF THE DEVICE