Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

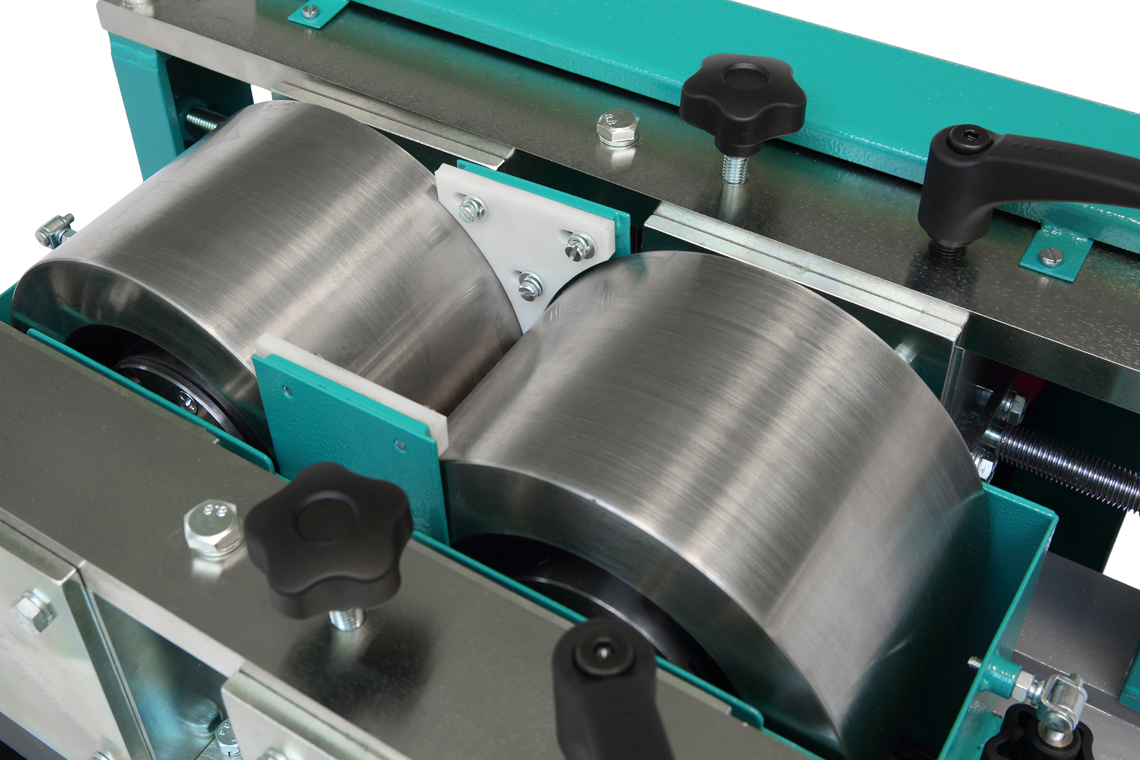

Double-roller Crusher DRC 200х125

|

INDUSTRIES

|

APPLICATIONS Granite, marble, diatomite, granodiorite, limestone, aluminum oxide, flux, glass, PVC, sugar.

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

| Average product particle size at minimum gap, mm | 0,3 |

| Product particle size at minimum gap, mm | 90%<0,5 |

| Maximum initial material grain size, mm* | 25 |

| Mohs hardness of crushed material, up to | 7 |

| Output, kg/hour* | 25-300 |

| TECHNICAL PARAMETERS | |

| Hopper loading door dimensions, mm | 160х200 |

| Crusher loading door dimensions, mm | 25х100 |

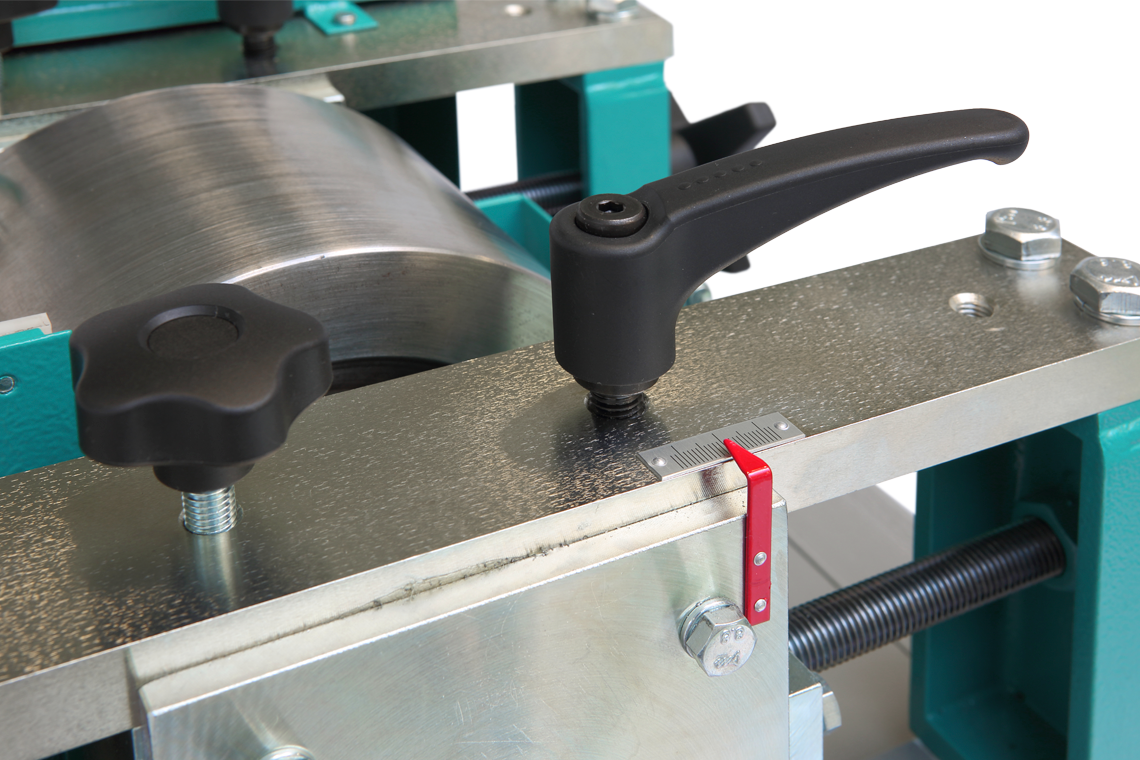

| Discharge slot adjustment range, mm | 0-12 |

| 50 Hz supply voltage, V | 380 |

| Electric motor power, kW | 2х1,1 |

| Rollers rotation speed, rpm | 650, 670 |

| Gross/usable capacity of the collecting container, l | 10/ 6,6 |

| Overall dimensions (Length x Width x Height), mm | 680х400х950 |

| Weight/weight with control panel, kg | 242 |

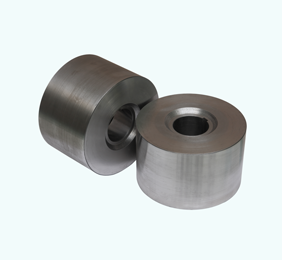

| Rollers material – tool steel | 105WCr6, 66Mn4, 90CrSi |

| Rollers hardness, HRC | 53-60 |

|

Control panel model |

* Depends on the physical properties of the material and the gap between rollers

ADVANTAGES

|

COMPATIBLE WITH VIBRATORY FEEDERS Completing with VF 1 or VF 2 Vibratory feeders provides:

|

|

|

CONTROL PANEL The control panel is designed to start and stop the crusher and provides:

|

|

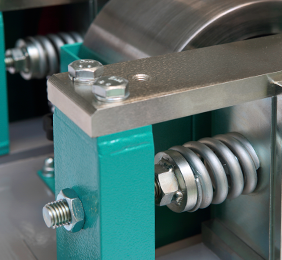

SPRING BLOCK A block of springs protects the crusher from breakdowns due to the indestructible object, and adjusting the preload force reduces the over- or under-grinding of the crushed material. |

|

|

QUALITY SPARE PARTS Rollers are made of tool steel AISI 1066. Complete with a special wrench for replacing the rollers. |

DESCRIPTION OF THE DEVICE

|

The principle of operation of the roll crusher is based on the abrasion (simultaneous compression and shear deformation) of the material between the rollers rotating towards each other. The grain size of the crushing product is determined by the gap between the rollers, the compressive force of the springs and the physical properties of the material. The structure of DRC 200x125 Double-roller crusher includes: loading hopper, frame, rollers, adjusting mechanism, spring block, receiving container and electric motors. The roller housings are fixed on the frame. One roller is installed through the spring block, and the second through the adjusting mechanism. The torque from the electric motors is transmitted to the rollers through belt drives with different gear ratios. OPERATING PRINCIPLE The initial material is fed into the loading hopper funnel, from where it enters the rollers rotating towards each other. Between the rolls, the particle receives a single effect and passes into the unloading zone. Once an indestructible object enters the rollers, it squeezes the roll on the springs and passes into the receiving container, without damaging the crusher. PRODUCTION OPTIONS

SPECIAL OPTIONS:

|

Rollers and fluoroplastic overlays Gap adjustment device Adjustment knob and handle

DRC 200x125 Double-roller crusher with dust collector |

.png)

.png)

.png)

.png)