Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

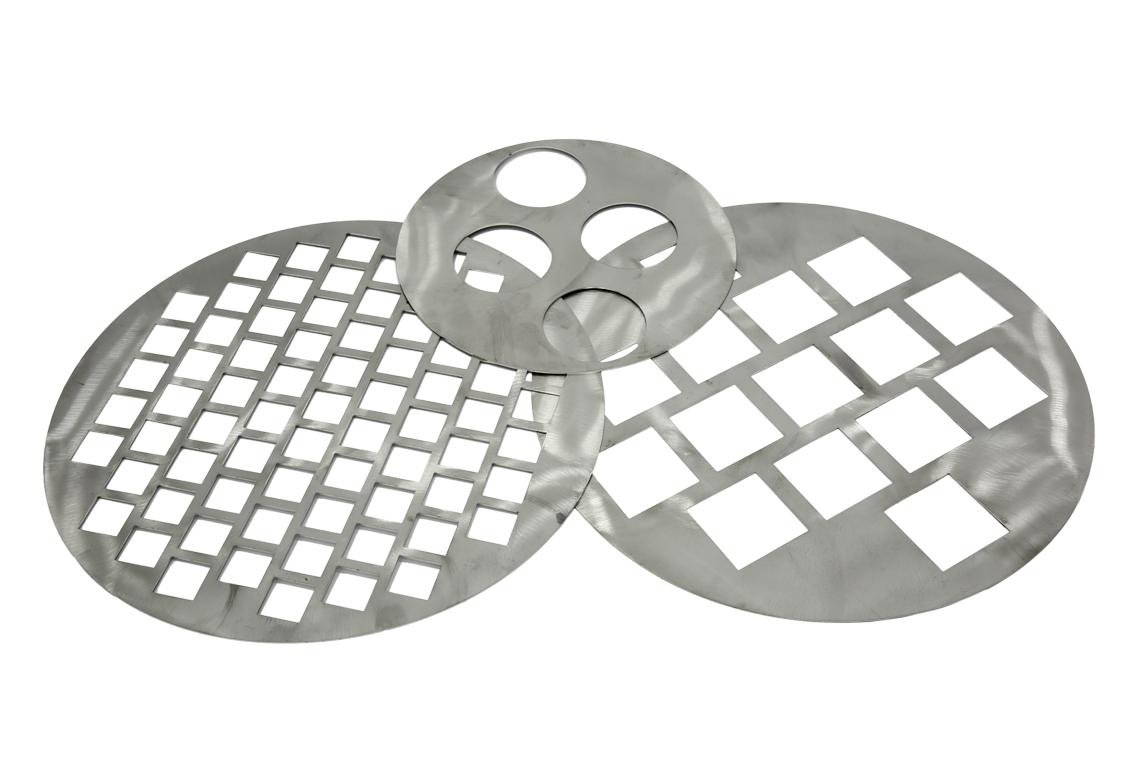

Sieve for Circular Vibratory Screener CVS 30

|

INDUSTRIES

|

APPLICATIONS Diamonds, ferroalloys, ore, metal powders, coal, glass, ceramics, polymers, peat, cereals, coffee.

|

CHARACTERISTICS

|

PARAMETERS |

VALUES |

|

Inner frame diameter, mm |

300 |

|

Mesh size, mm |

0,315-2,8 |

|

Size of apertures in perforated plate, mm |

0,8-3,0 |

|

Weight, up to, kg |

1,2 |

| Sieving element type and material | |

| Mesh material | stainless steel, brass |

| Perforated plate material | stainless steel |

|

Mesh size of metal fabric screens |

||||||||

|

Cell size, mm |

0,315 |

0,355 |

0,4 |

0,45 |

0,5 |

0,56 |

0,63 |

|

|

Material |

brass, s.steel |

brass, s.steel |

brass, s.steel |

brass, s.steel |

brass, s.steel |

brass |

brass, s.steel |

|

|

Cell size, mm |

0,7 |

0,8 |

0,9 |

1 |

1,1 |

1,2 |

1,25 |

|

|

Material |

brass, s.steel |

brass, s.steel |

brass, s.steel |

brass, s.steel |

s.steel |

s.steel |

brass, s.steel |

|

|

Cell size, mm |

1,4 |

1,6 |

1,8 |

2 |

2,2 |

2,5 |

2,8 |

|

|

Material |

s.steel |

brass, s.steel |

s.steel |

brass, s.steel |

s.steel |

brass, s.steel |

s.steel |

|

|

Size and shape of apertures in perforated plate |

||||||

|

Aperture Diameter, mm |

0,8 |

1,0 |

1,5 |

2,0 |

2,5 |

3,0 |

ADVANTAGES

|

NO CROSS-CONTAMINATION OF SAMPLES The sieve frame is made of stainless steel (AISI 304). The ingress of sample particles between the frame and the screening element is excluded due to their tight fit to each other. SIEVE SHAKERS COMPATIBILITY CVS 30 sieves can be used in Circular vibratory screener CVS 30 based on VD 30, VD 30T, VPS or VD 50 vibration drive. |

|

MESH MATERIAL

|

|

|

CALIBRATION CERTIFICATE Production quality is confirmed by a calibration certificate. |

DESCRIPTION OF THE DEVICE

|

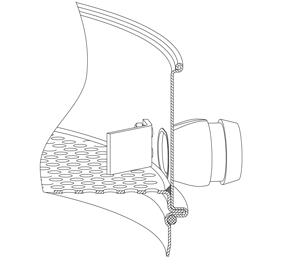

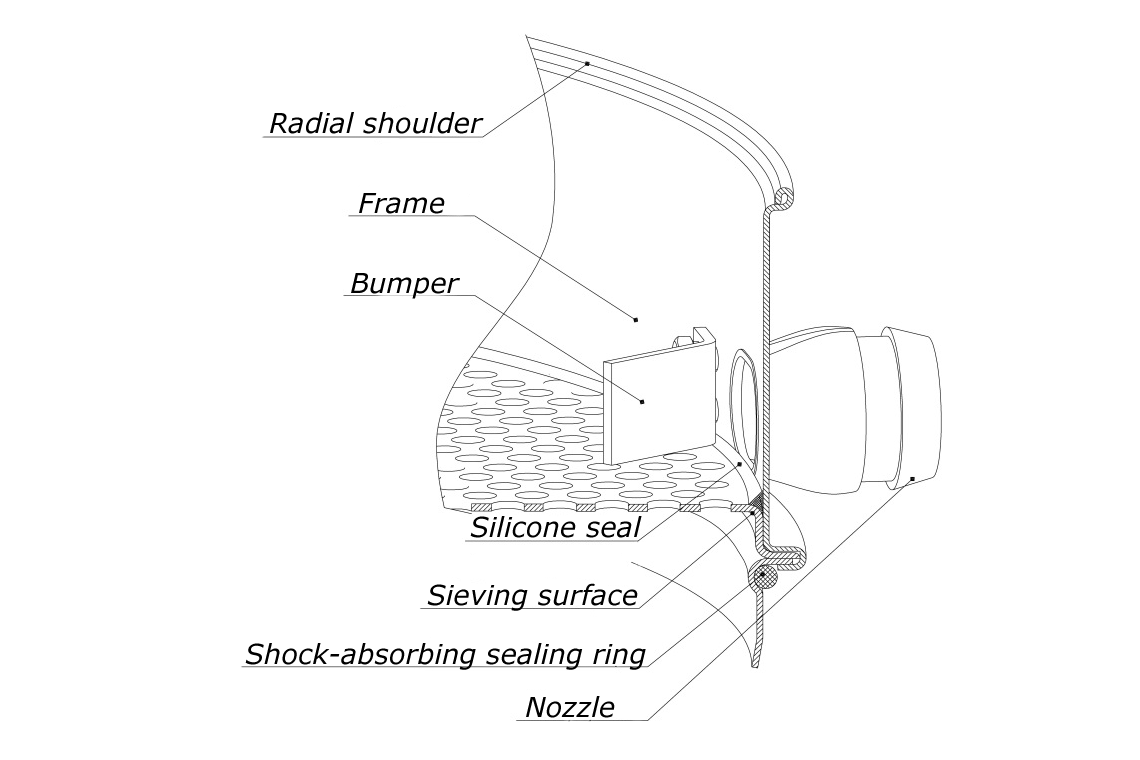

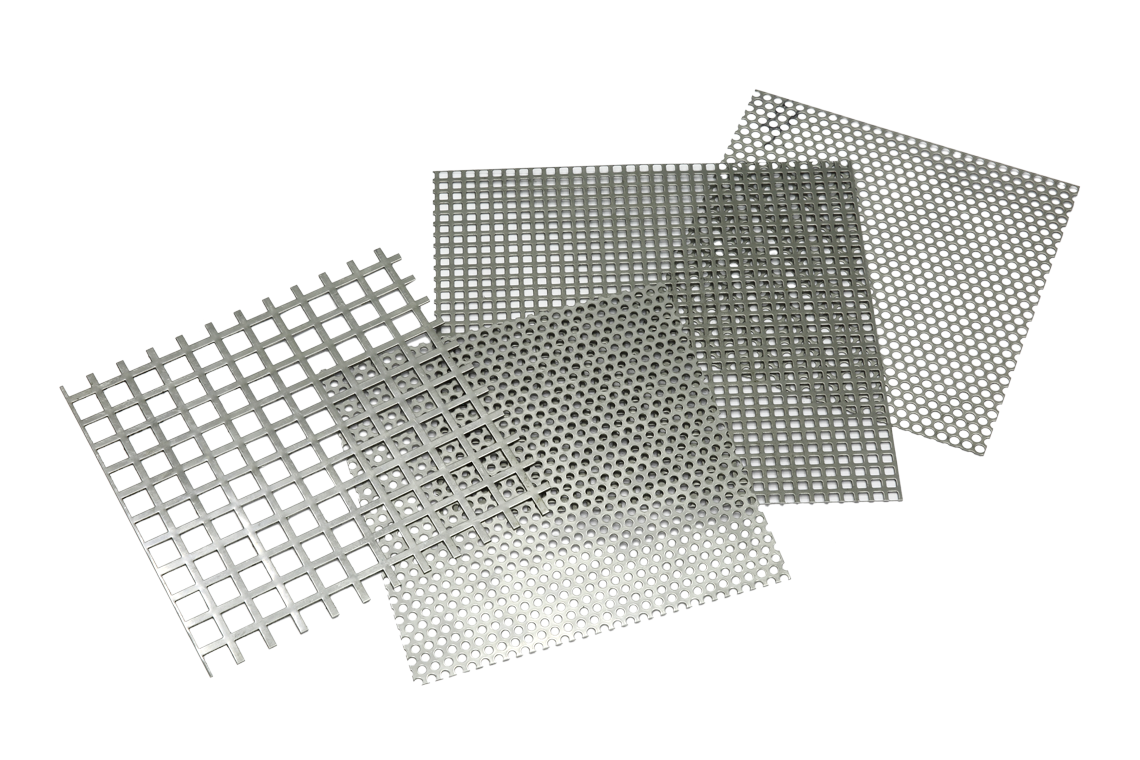

CVS 30 Screener sieve consists of a frame, a sieving surface, a discharge nozzle, a bumper and a shock-absorbing sealing ring. In the place of attachment of the sieving surface and on the upper end of the frame, radial shoulders are made, which ensure the rigidity of the sieve. The sieving element is tightly attached to the frame, witch exclude the ingress of material between the frame and the sieving surface. Labeling is performed by laser engraving. The shock-absorbing sealing ring eliminates the possibility of impacting the ends of the sieves and provides a tight connection between the sieves, with the intermediate rings, trays and covers. CVS 30 Screener sieve can be equipped with stainless steel or brass mesh. Types of perforated plates:

OPERATING PRINCIPLE The sieving of the material is carried out using one or more screener sieves, a tray and a cover. The number of sieves, as well as the mesh size or the size and shape of the perforated plate apertures are determined by the conditions of the analysis. The material to be sieved is loaded into the upper sieve. The sieve column complete with tray and cover must be shaken using a VD 30, VD 30T, VPS or VD 50 vibration drive. Using the vibration drive allows to increase productivity of sieving due to high-frequency reciprocating screw oscillations of the platform on which the column of sieves is fixed. Particles of material which are smaller than the size of the sells / apertures in the sieving surface of the upper sieve fall through on the next sieve, where the cycle repeats; larger particles move along the surface of the screening element and, due to the bumper, fall into the nozzle and are unloaded from the sieve into the receiving containers. As a result, the material is distributed in the receiving containers in accordance with the fractional content. |

CVS 30 sieve scheme Standard perforated plates Zone perforation plates

Laser perforation plates |

.png)

.png)

.png)