Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

Sieve S 12R

|

INDUSTRIES

|

APPLICATIONS Diamonds, ferroalloys, ore, metal powders, coal, glass, ceramics, polymers, peat, cereals, coffee.

|

CHARACTERISTICS

|

PARAMETERS |

VALUES |

||||||||||||

|

Inner frame diameter, mm |

100 |

||||||||||||

|

Mesh size, mm |

0,02 — 2,5 |

||||||||||||

| Weight, up to, kg | 1 | ||||||||||||

| Maximum load on the sieve with mesh, kg | 0,1 | ||||||||||||

| Sieving element type and material | |||||||||||||

| Mesh material | stainless steel, brass, bronze, polyamide | ||||||||||||

Mesh size of metal fabric screens

| Cell size, mm |

0,02 |

0,032 |

0,04 |

0,045 |

0,05 |

0,056 |

0,063 |

|

|

Material |

s.steel |

s.steel |

bronze, s.steel |

bronze |

bronze |

bronze, s.steel |

bronze, s.steel |

|

|

Cell size, mm |

0,064 |

0,071 |

0,074 |

0,08 |

0,09 |

0,094 |

0,1 |

|

|

Material |

s.steel |

brass, s.steel |

s.steel |

brass, s.steel |

brass |

s.steel |

brass, s.steel |

|

|

Cell size, mm |

0,112 |

0,125 |

0,14 |

0,16 |

0,18 |

0,2 |

0,25 |

|

|

Material |

brass |

brass, s.steel |

brass, s.steel |

brass, s.steel |

brass |

brass, s.steel |

brass, s.steel |

|

|

Cell size, mm |

0,28 |

0,315 |

0,355 |

0,4 |

0,45 |

0,5 |

0,56 |

|

|

Material |

brass |

brass, s.steel |

brass, s.steel |

brass, s.steel |

brass, s.steel |

brass, s.steel |

brass |

|

|

Cell size, mm |

0,63 |

0,7 |

0,8 |

0,9 |

1 |

1,1 |

1,2 |

|

|

Material |

brass, s.steel |

brass, s.steel |

brass, s.steel |

brass, s.steel |

brass, s.steel |

s.steel |

s.steel |

|

|

Cell size, mm |

1,25 |

1,4 |

1,6 |

1,8 |

2 |

2,2 |

2,5 |

|

|

Material |

brass, s.steel |

s.steel |

brass, s.steel |

s.steel |

brass, s.steel |

s.steel |

brass, s.steel |

|

Polyamide mesh cell size

|

Cell size, mm |

0,029 |

0,035 |

0,046 |

0,056 |

0,057 |

0,062 |

0,067 |

0,074 |

0,082 |

0,087 |

0,093 |

0,099 |

0,1 |

|

0,104 |

0,106 |

0,108 |

0,112 |

0,114 |

0,115 |

0,118 |

0,119 |

0,122 |

0,124 |

0,125 |

0,13 |

0,132 |

|

|

0,134 |

0,137 |

0,14 |

0,142 |

0,144 |

0,148 |

0,15 |

0,154 |

0,157 |

0,158 |

0,16 |

0,163 |

0,164 |

|

|

0,175 |

0,178 |

0,18 |

0,182 |

0,183 |

0,188 |

0,193 |

0,194 |

0,195 |

0,2 |

0,203 |

0,206 |

0,212 |

|

|

0,213 |

0,224 |

0,245 |

0,25 |

0,265 |

0,3 |

0,315 |

0,335 |

0,355 |

0,363 |

0,39 |

0,425 |

0,45 |

|

|

0,475 |

0,5 |

0,512 |

0,56 |

0,6 |

0,67 |

0,71 |

0,8 |

0,85 |

0,95 |

1 |

1,18 |

1,68 |

ADVANTAGES

|

MESH MATERIAL

|

|

|

SIEVE RIGIDITY The thickness of the sieve frame is 1.5 mm, which eliminates its breakage or deformation.

|

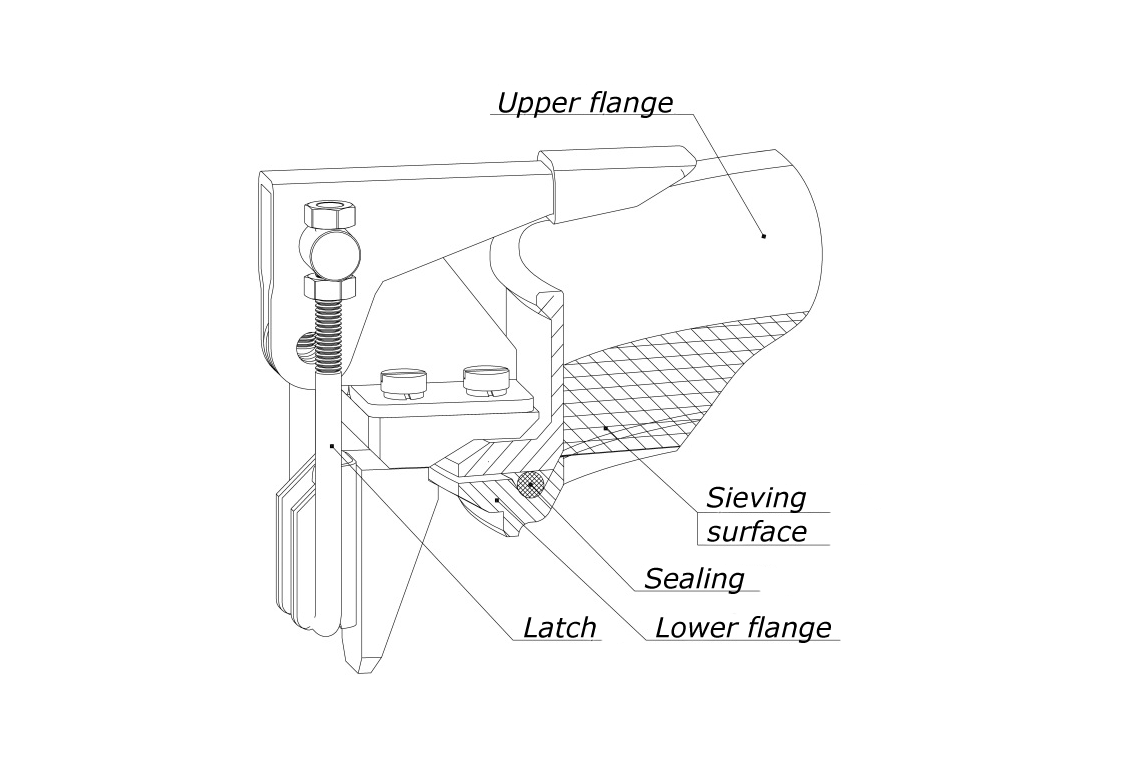

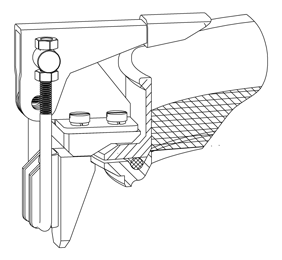

DESCRIPTION OF THE DEVICE

|

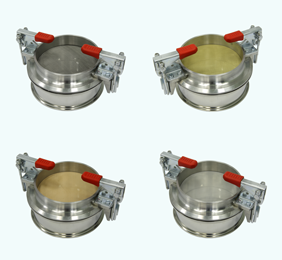

S 12R laboratory sieve consists of the upper and lower flanges, two latches, a sieving element and sealing. Sealing placed between the flanges provides a mesh tension. Labeling is performed by laser engraving. Mesh material

OPERATING PRINCIPLE The sieve analysis is performed using a sieve and a tray. The mesh size is determined by the conditions of the analysis. The sieve is mounted on a tray; the material to be sieved is loaded into the sieve. The sieve complete with tray must be shaken using a VD 30, VD 30T, EVD Electromagnetic vibration drive. Using the vibration drive allows to increase productivity of sieving due to high-frequency reciprocating screw oscillations of the platform on which the sieve is fixed. Particles of material which are smaller than the size of the sells in the sieving surface of the sieve fall through into the tray. As a result, the sample is distributed between the sieve and the tray in accordance with the fractional content. At the end of the sieving process, the contents of the sieve and the tray are weighed and the particle size distribution of the sample is determined. |

S 12R scheme |

.png)

.png)

.png)