Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

Soil grinder SG 1

|

INDUSTRIES

|

APPLICATIONS Peat, red soil, black soil

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

| Average comminuted product particle size with grate with 1 mm opening, mm | 0,25-0,5 |

| Comminuted product particle size with grate with 1 mm opening, mm | 100%<1,0 |

| Maximum initial material grain size, mm | 20 |

| Output, sample/hour* | 20-40 |

| Mohs hardness of initial material, up to | 2 |

| TECHNICAL PARAMETERS | |

| Hopper loading door dimensions, mm | 145х140 |

| Grinder loading door dimensions, mm | 37х145 |

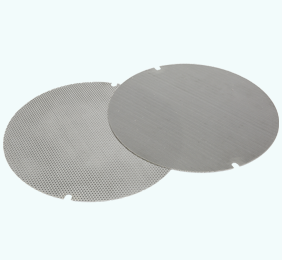

| Size of discharge grate openings, mm | 1 or 2 |

| 50 Hz supply voltage, V | 380 |

| Motor-reducer power, kW | 0,75 |

| Shaft rotational speed, rpm | 75 |

| Gross/usable capacity of the collecting container, l | 2/ 1,4 |

| Overall dimensions without/with support stand and control panel (Length x Width x Height), mm | 640х465х720/ 690х645х1315 |

| Weight/weight with support stand and control panel, kg | 60/140 |

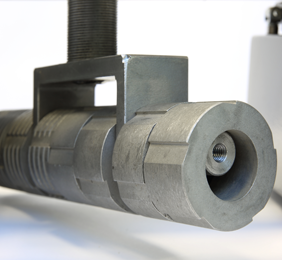

| Rollers material – tool steel | 105WCr6 |

| Rollers hardness, HRC | 48-52 |

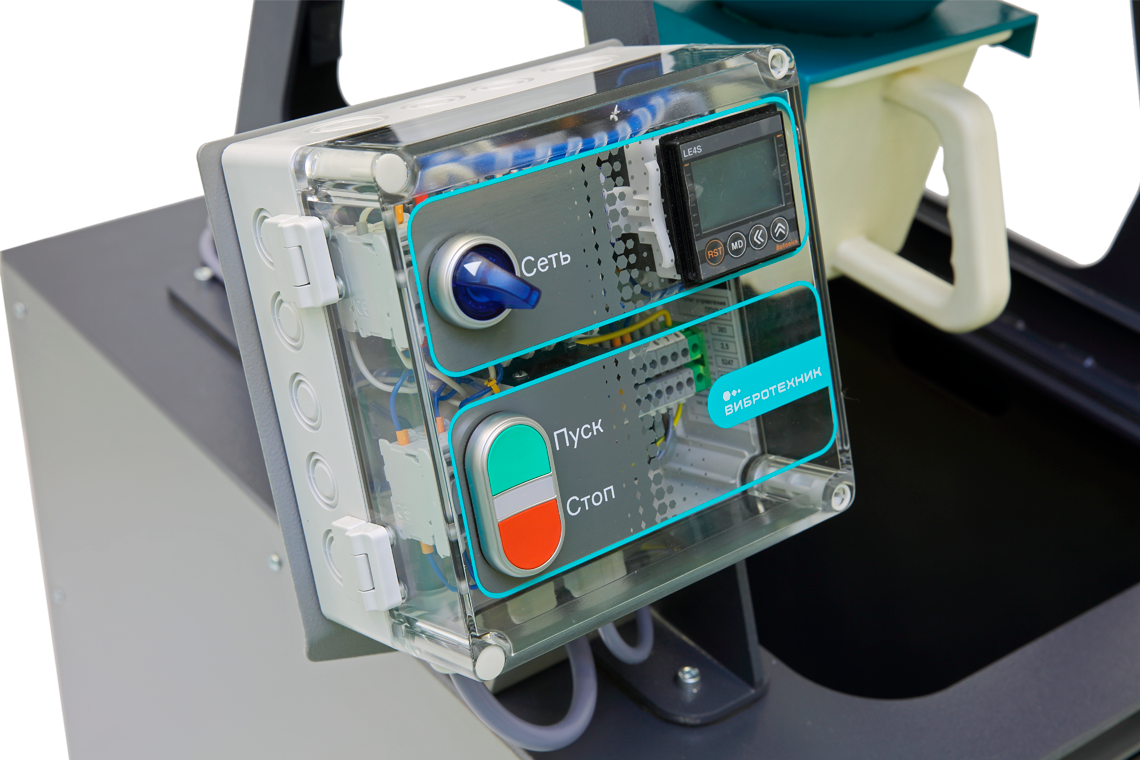

| Compatible control panel | PCP3-04 (with the timer) |

* for samples weighing 0.5 kg each

ADVANTAGES

|

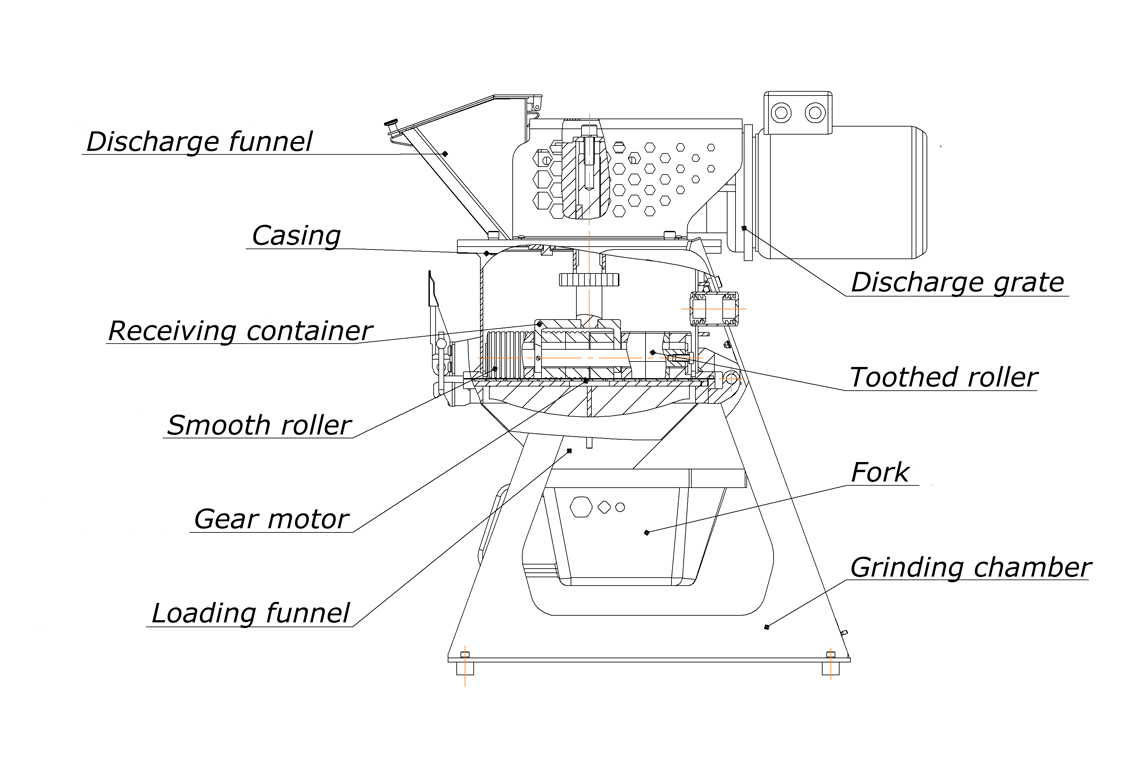

SELECTIVE GRINDING Free suspension of the rollers ensures comminution of dry soil samples without grinding plant inclusions and stones. |

|

|

FOLDING DISCHARGE FUNNEL Folding discharge funnel provides:

|

|

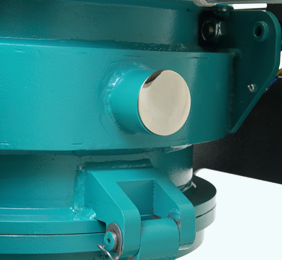

ROTATING CHAMBER 90° rotation and locking of chamber provide easy maintenance and cleaning. |

|

|

COMPATIBLE WITH DUST EXTRACTION SYSTEM A special nozzle allows connecting SG1 Soil grinder to the aspiration system to remove dust from the grinding chamber. |

|

QUALITY SPARE PARTS The rollers and the axis of the fork are made of wear-resistant tool steel. The discharge grates are made of stainless steel. |

DESCRIPTION OF THE DEVICE

.png)

.png)