Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

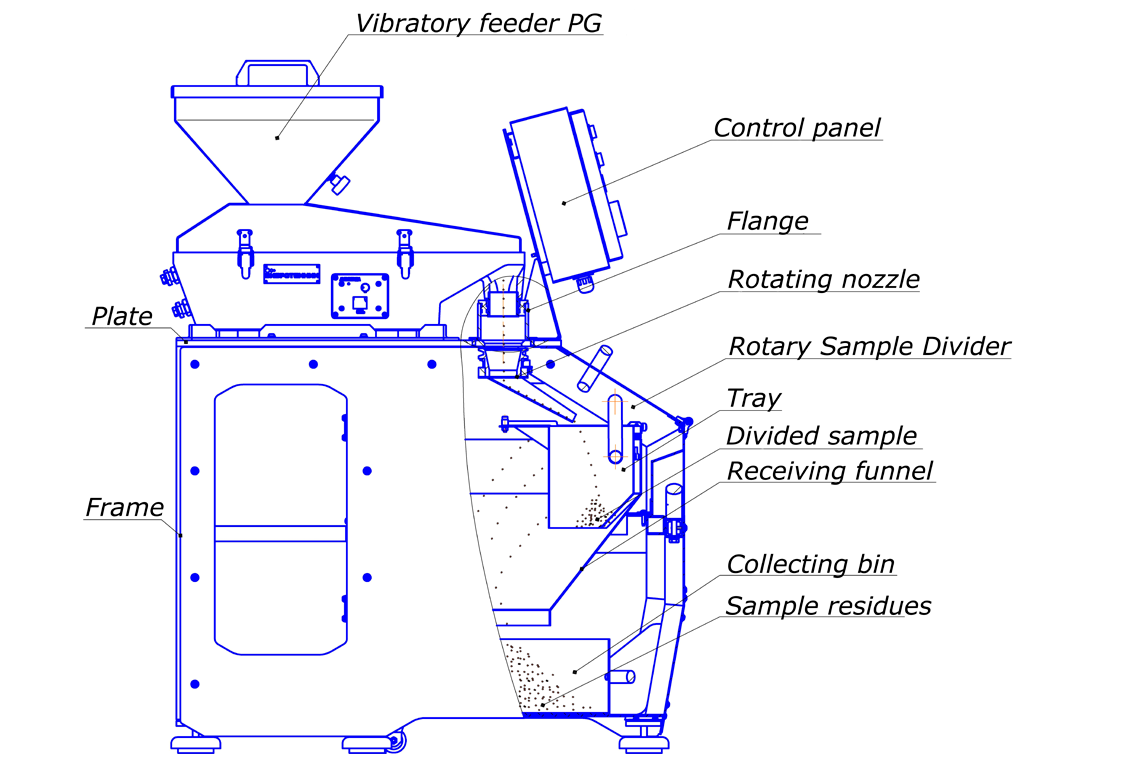

Rotating sample divider RSDM with Vibratory feeder VF 1

|

INDUSTRIES

|

APPLICATIONS Ferroalloys, ore, granite, marble, limestone, coal, slag, cement, glass, ceramics, medicines and pharmaceuticals.

|

CHARACTERISTICS

|

PARAMETERS |

RSDM with VF1 |

RSDM with VF2 |

| Technological parameters | ||

| Maximum material feed size, mm |

10 |

|

| Maximum output, kg/hour |

200 |

|

| Reduction |

1/2 — 1/100 |

|

| Technical parameters | ||

| Gross/usable capacity of the feeder hopper, l |

12/9 |

72/66 |

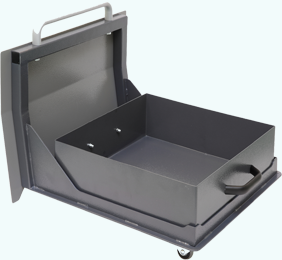

| Gross/usable capacity of the receiving bin on a roll-out trolley, l |

19/ 12,5 |

|

| Tray vibration amplitude, up to, mm | 0,2 | |

| 50 Hz supply voltage, V | 220 | |

| Feeder drive power, kW | 50 | |

| Motor-reducer power, kW | 70 | |

| Divider nozzle rotation speed, rpm | 60 | |

| Overall dimensions (Length x Width x Height), mm | 870х725х1120 | 1030х760х1345 |

| Weight/weight with control panel, kg | 180 | 190 |

| Feeder hopper, tray, nozzle and divider nozzle material | AISI 304** | |

| Compatible control panel | MCPU1-04 | |

* Depends on the density of the material

ADVANTAGES

|

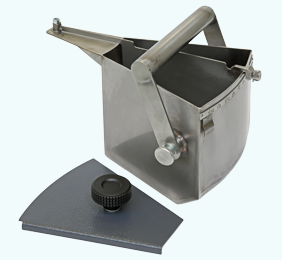

ACCURACY OF REDUCTION VF 1 Vibratory feeder provides an adjustable supply of material from the hopper through the discharge nozzle. Since the rotation speed of the trays of the divider is constant, the sample is dividing between the trays proportionally to their volume. OPERATIONAL SAFETY The rotating elements of the divider are covered by casing. The end switch excludes start-up of the divider with the cover open. In the open position, the cover is securely fixed. NO SAMPLE CONTAMINATION The loading hopper, tray and discharge nozzle of the feeder, as well as the adjustable tray of the divider are made of stainless steel AISI 321. |

|

ADJUSTABLE DEGREE OF REDUCTION Tray with a movable partition provides a smooth adjustment of the degree of reduction from ⅛ to 1/80 of the total sample volume.

|

|

|

COMPATIBLE WITH CONTROL PANEL The control panel is designed to start and stop the equipment and provides:

The control panel eliminates the start of the Vibratory feeder when the Sample divider is off. |

DESCRIPTION OF THE DEVICE

.png)