Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

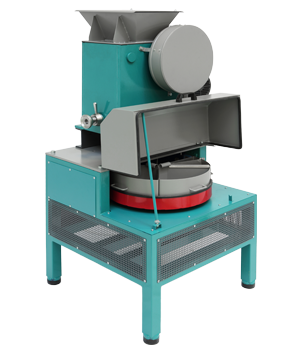

Crushing divider unit with JC 10

|

INDUSTRIES

|

APPLICATIONS Ferroalloys, ores, slags, granite, marble, limestone, coal, coke, glass, ceramics.

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

| Average product particle size at minimum gap, mm | 0,7-1,5 |

| Product particle size at minimum gap, mm | 90%<2,5 |

| Maximum initial material grain size, mm* | 70 |

| Mohs hardness of crushed material, up to | 8** |

| TECHNICAL PARAMETERS | |

| Hopper loading door dimensions, mm | 265х365 |

| Crusher loading door dimensions, mm | 100x200 |

| Discharge slot adjustment range, mm | 2,5-35 |

| Reduction | 1/2 — 1/100 |

| 50 Hz supply voltage, V | 380 |

| Crusher motor power, kW | 2,2 |

| Divider motor-reducer power, kW | 70 |

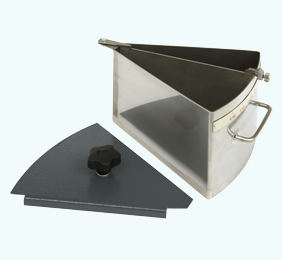

| Gross/usable capacity of the receiving bin on a roll-out trolley, l | 19/12,5 |

| Overall dimensions (Length x Width x Height), mm | 860х760х1405 |

| Weight, kg | 445 |

| Jaw material – iron / steel / tungsten carbide | EN-GJN-HV600 (XCr14) / GX120Mn13 / tungsten carbide |

| Jaw hardness – iron / steel / tungsten carbide | 52-55/ 31-32 HRc/ 1180-1280 HV |

| Armor lining material — tool steel | 66Mn4 |

| Armor lining hardness, HRC | 31-32 |

|

Compatible control panel |

|

* Depends on the hardness of the material and the discharge slot setting.

** When using jaws made of tungsten carbide.

ADVANTAGES

|

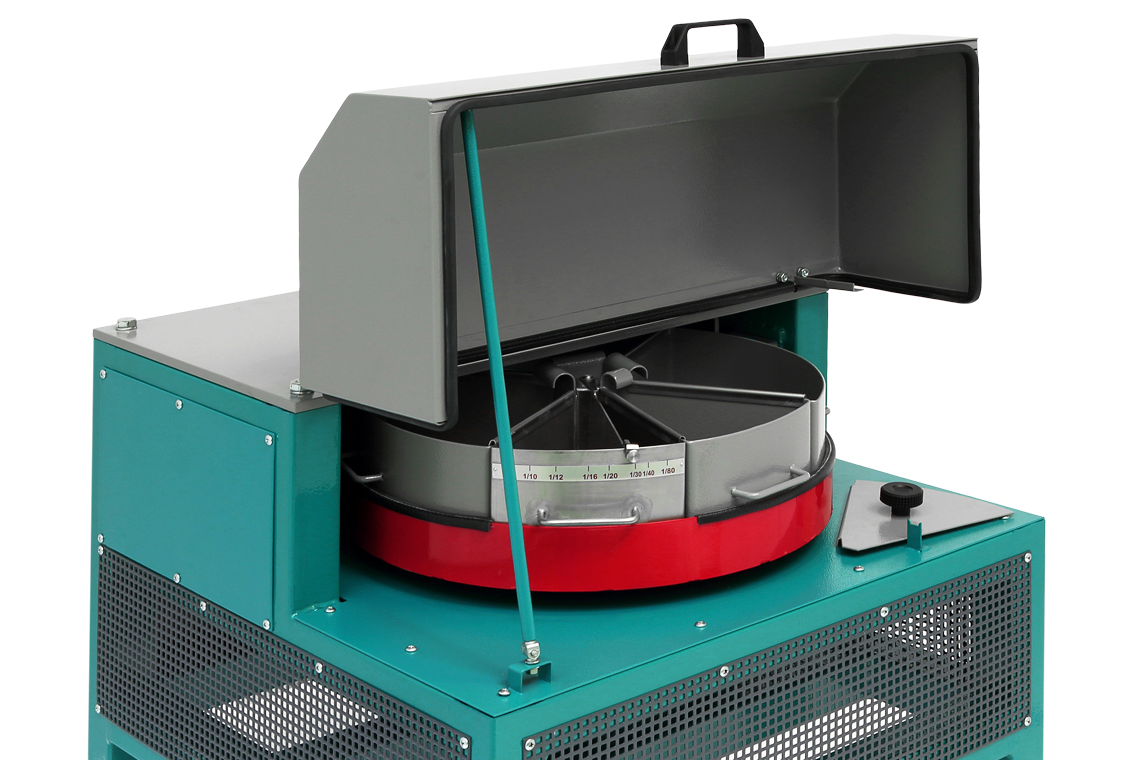

CRUSHING EFFICIENCY The «tooth- trough» jaws combination provides high crushing performance. SIMULTANEOUS CRUSHING AND REDUCTION The combination of JC 10 jaw crusher and Rotating sample divider into a single technological complex eliminates the stage of sample overload, which reduces dusting and increases productivity. OPERATIONAL SAFETY The rotating elements of the divider are covered by casing. The end switch excludes start-up of the divider with the cover open. In the open position, the cover is securely fixed. |

|

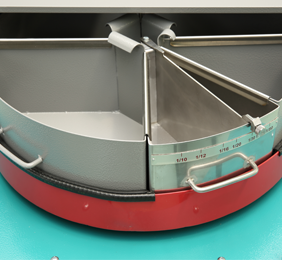

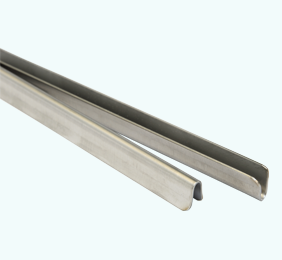

ADJUSTABLE TRAY FOR ROTATING SAMPLE DIVIDER Tray with a movable partition provides a smooth adjustment of the degree of reduction from ⅛ to 1/80 of the total sample volume. |

|

|

NO LOSS OF SAMPLE MATERIAL Tight installation of the trays, as well as the sealing between them, excludes the spilling of the sample past the trays. |

|

|

COMPATIBLE WITH CONTROL PANEL The control panel is designed to start and stop the equipment and provides:

The control panel eliminates the start of the Jaw crusher when the Rotating sample divider is off. |

DESCRIPTION OF THE DEVICE