Maliy pr. V. O., 62/2, liter A, St. Petersburg, Russian Federation, 199178

Vibrating cone mill VCM 6

|

INDUSTRIES

|

APPLICATIONS Ferroalloys, ore, coal, slag, ceramics, glass, limestone, soda, smalt, diatomaceous earth.

|

CHARACTERISTICS

|

TECHNOLOGICAL PARAMETERS |

|

| Average product particle size at minimum gap, mm | 60-100 |

| Product particle size at minimum gap, mm | 90%<250 |

| Maximum initial material grain size, mm* | 5 |

| Mohs hardness of crushed material, up to | 7 |

| Output, kg/hour* | 1-20 |

| TECHNICAL PARAMETERS | |

| Loading door dimension, mm | Ø95 |

| Crushing zone loading door dimension, mm | Ø51 |

| Discharge slot adjustment range, mm | 0-5 |

| 50 Hz supply voltage, V | 220/380 |

| Electric motor power, kW | 1,5/0,55 |

| Leading debalance speed, rpm | 2250; 2500 |

| Gross/usable capacity of the collecting container, l | 0,8/0,5 |

| Overall dimensions (Length x Width x Height), mm | |

| with 220 V electric motor | 485х235х370 |

| with 380 V electric motor | 350х235х395 |

| Weight/weight with control panel, kg | |

| with 220 V electric motor | -/ 40 |

| with 380 V electric motor | -/ 45 |

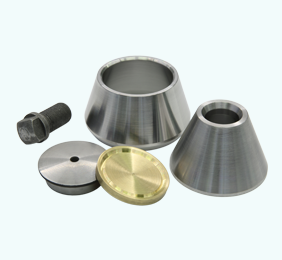

| Cones material – tool steel | 105WCr6 |

| Cones hardness, HRC | 55-62 |

|

Control panel model |

|

* Depends on the physical properties of the material and the gap between cones

ADVANTAGES

|

CONTROL PANEL The control panel is designed to start and stop the mill and provides:

|

|

|

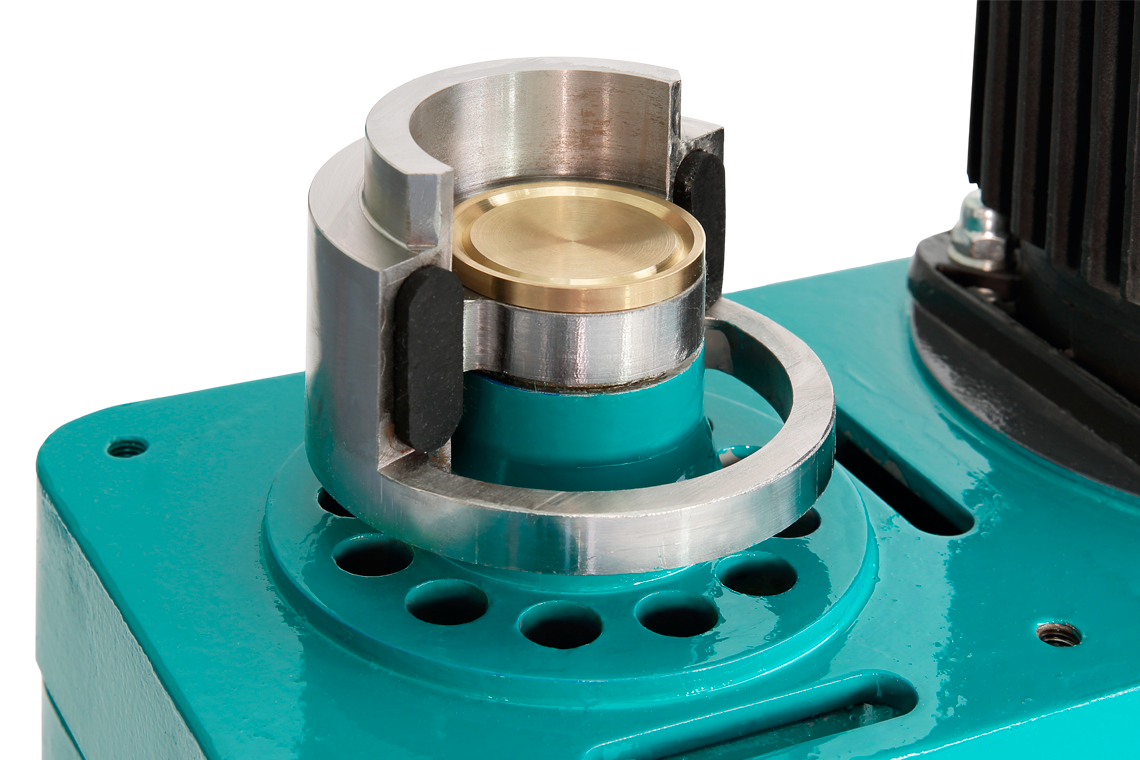

QUALITY SPARE PARTS The inner and outer shells are made of tool steel. The saddle of the driven debalance is made of bronze. |

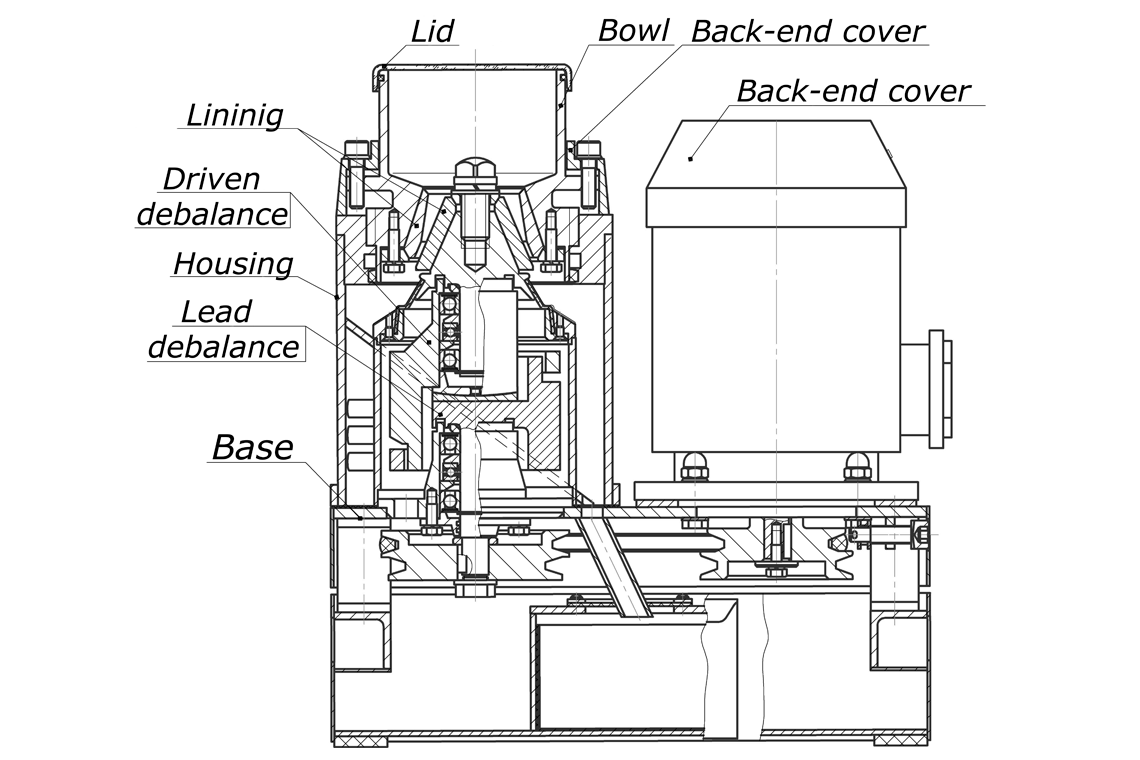

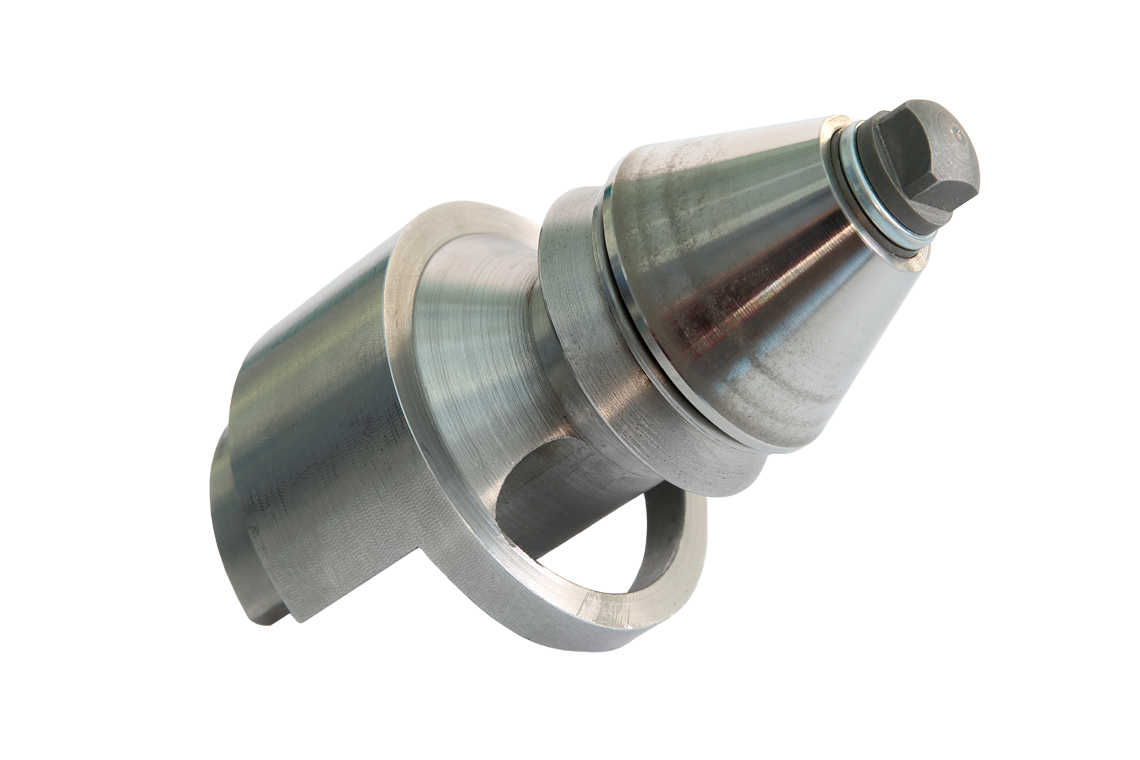

DESCRIPTION OF THE DEVICE

Ask a Question

.png)

.png)